How TPM can work in Industry 4.0 environment?

In my article Lean Industry 4.0 I tried to explain how organisations can benefit from the hybrid approach Lean Industry 4.0 . So, in this article I am trying to explain how the lean tools will work on 4.0 environment.

As, we know, Industry 4.0 is the integration of current technological trends in manufacturing which is a combination of cyber physical systems like Internet of Things and Internet of Systems etc. The previous revolution involved implementing computers in manufacturing while this transition is all about the smart interrelation of systems, it’s communication as well as decision making without human intervention. Industry 4.0 aims to alter the present mechanism of designing, manufacturing and of its services. The present dilemma of manufacturers is whether they can commit into this revolution considering the investment and its outcomes.

How does this revolution influence lean?

For years, operators and manufacturers have been using lean to decrease complexity and improve their outcomes. Lean then, lean now and always will be about obtaining the maximum output with the minimum input. The building blocks of lean are its people and not gadgets therefore Industry 4.0 will become a part of lean. Lean principles will enable the transition as well as it makes an organisation lean as well as smart. The fourth industrial revolution can empower the true lean enterprise. As researches suggests, Industry 4.0 technologies may be exactly what we need in order to create lean supply chains and networks. The digitisation of machinery points towards the automation of lean and hence achieve it with the current technological trends. The fundamental principles won’t be affected while new add-on such as data collection, process tracking & management, better communication mechanisms etc will give existing methodologies a new face. This is the most effective way to reach a consecutive level of operational excellence.

Total Preventive Maintenance in Industry 4.0

As we know, CMMS is the software used to achieve Total Productive Maintenance and Overall Equipment Efficiency. The next generation maintenance systems are all about digital transformations such as adaptive manufacturing, advanced robotics, augmented reality, big data and analytics, cloud computing, cybersecurity, horizontal and vertical system integration, the industrial internet, and simulation. We know that Computerised Maintenance Management Systems can be integrated with cyber physical systems easily.

With the integration of Industry 4.0 along with lean, productive maintenance systems are able to connect to each other as well as transmit information to other systems. The interconnection of systems maybe across departments, locations etc. This information and analysis report help professionals make decisions during real business critical situations. With the right analysis, the systems can predict failure, reconfigure themselves, and also adapt to change. Unpredicted breakdowns and maintenance can be handled well in such an atmosphere. Moreover, these systems do not require much human intervention and can be accessed anywhere. 4th level predictive maintenance will be the analysis of big-data by continuous real-time monitoring of assets that sends alerts based on predictive techniques such as regression analysis.

How can Industry 4.0 improve Total Productive Maintenance?

- Reduced Error Rates

- Faster Execution Systems

- Improved Efficiency

- Better Communicating Systems

- Enhanced Lifetime of machineries

- Maintenance expert time can use for higher level of tasks

- Failure prediction and zero down time

- Preventive task prescription

This revolution will not only optimise the equipment’s performance but also improve human and machine interaction. With Industry 4.0 around the corner, manufacturers can boost the pace of business output, help synchronisation of assets and even facilitate self-managing factory operations.

Start Free Trial

LEAN TRANSITION SOLUTIONS

The Old Vicarage, Pershore Road, Upton Snodsbury, Worcester, Worcestershire, WR7 4NR, United Kingdom.

BLOG

Lean Transition Solution

-

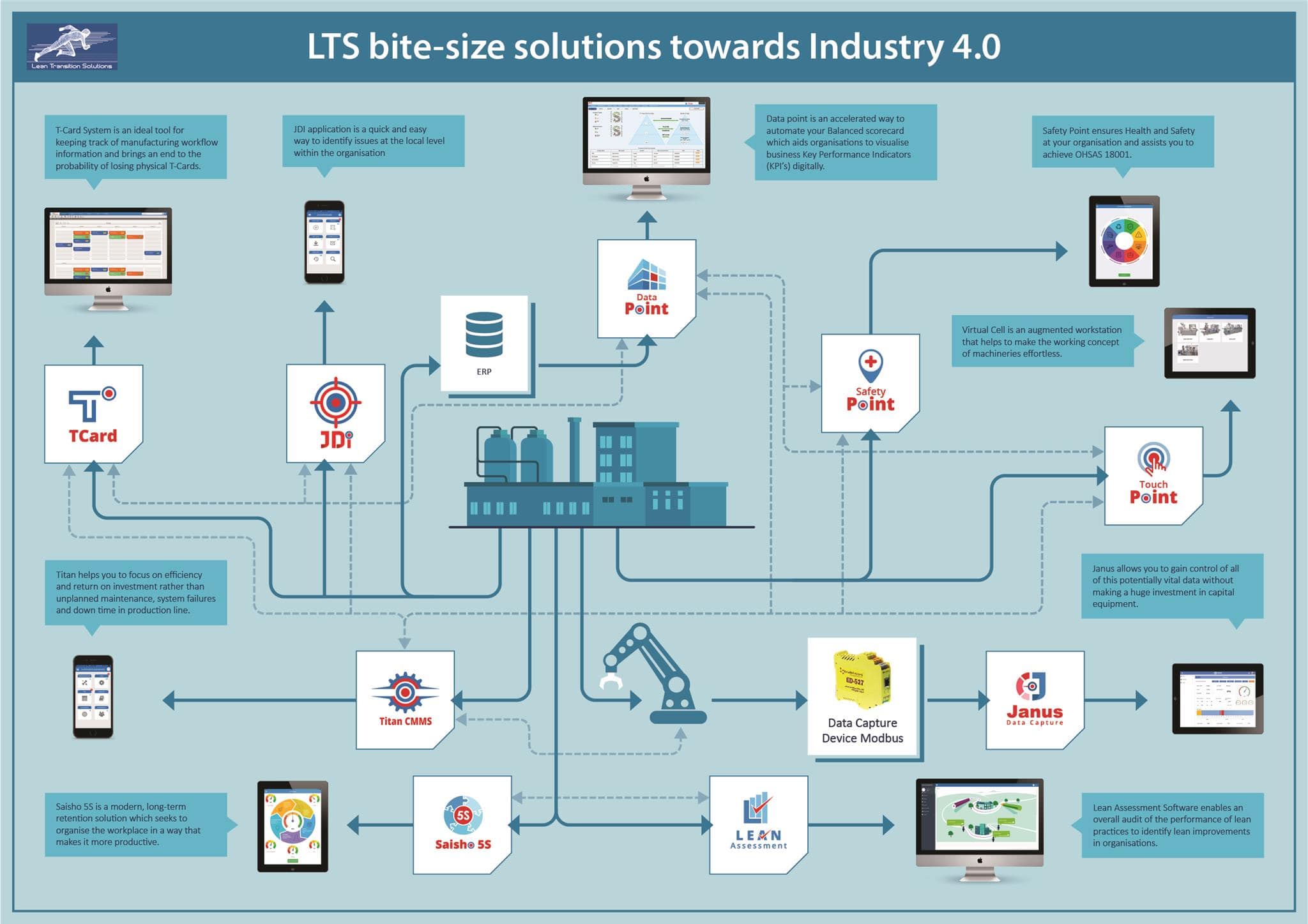

Lean Industry 4.0 Solutions

- TITAN:Computerised Maintenance Management System

- Data Point:Computerised Balanced Scorecard

- Janus: Automated Shop-floor Data Capture System

- T-Card: Integrated Production Planning and Plant Level Execution System

- JDI: Maintenance Automation App

- Maximus: Integrated ERP System

- e-Contractor: Integrated In-house Contractor Management System

- Q-Point: Integrated Quality Management System

- Safety-Point: Integrated Health and Safety Management System

- Lean Assessment: Lean Audit and Assessment System

- Saisho: Lean 5S Audit and Assessment App

- Emergency Response App: To Manage Emergency Situations

-

Leadership 4.0 Solutions

- Your Career Academy(YCA): Learning and Development System

- YCA e-Learning : Management System

- MentorYou(MU): Mentoring App

- Leadership 4.0 : Leadership Transformation Program

- Lean Manufacturing Workshop

- Lean Manufacturing Consulting

- ILM Accredited Green Belt Training and Certification Program

- ILM Accredited Black Belt Training and Certification Program

- Software Development Service

- Resources

- Company

- Contact