T-Card: Integrated Production Planning, Scheduling and Execution System

- Easy to Track the Manufacturing Production Flow

- Production Planning and Execution

- Manufacturing Order and Work Order Management

- Work Order Scheduling and Capacity Planning

- Live Work Order Status Sync

- Oversees Key Information for Different Tasks

- Product Specifications

- Manages Different Type of Users

- Saves Time and Reduce Cost

T-Card: Integrated Production Planning and Execution System

T-Card Software

- Flexible

- Visibility

- Unlimited Cards

- Web-Based

- Activity Stream

- Drag and Drop

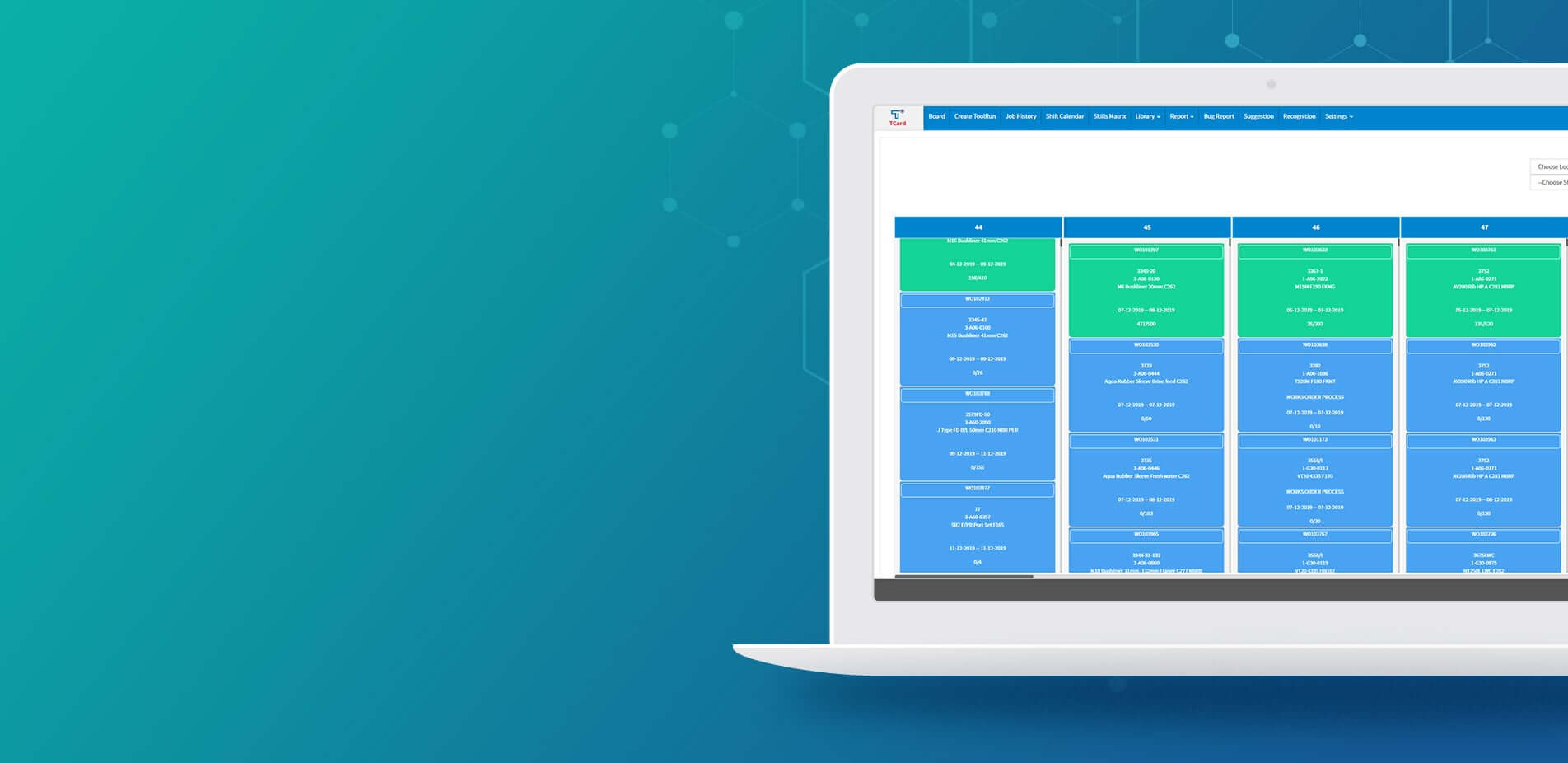

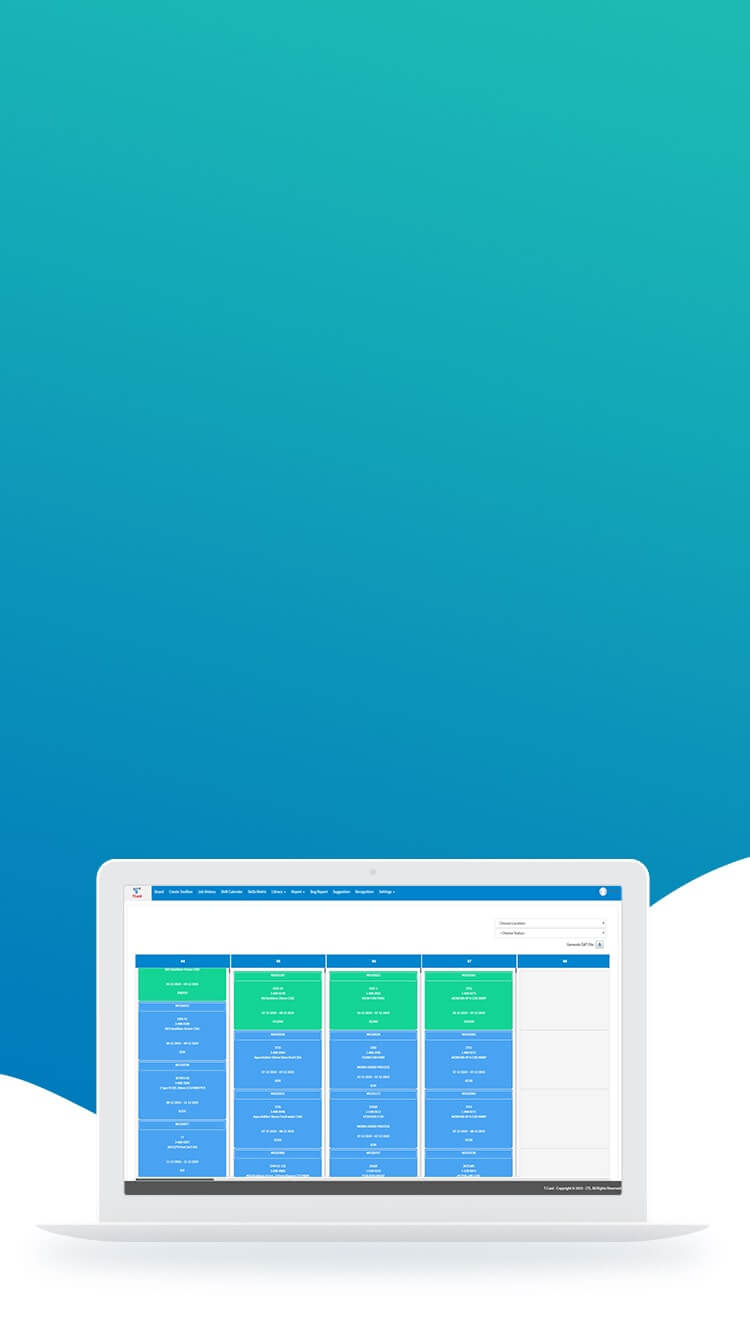

T-Card software is a web-based solution for production planning, employee scheduling and production execution. This web-based solution helps the manufacturer to transform the factory into an Industry4.0 environment. This system helps manufacturers to track their work order schedules and status. The physical T-card system limits the manufactures in many ways such as board size, card numbers, information on a card and biased production information. T-Card software solves all these problems and provides more flexibility.

- Displayed in the Production Area on TV Screens

- Individual and Team Board View

- Detailed Card Information with Specifications

- Manages a Checklist for Each Process

- Easy to Reschedule the Tasks

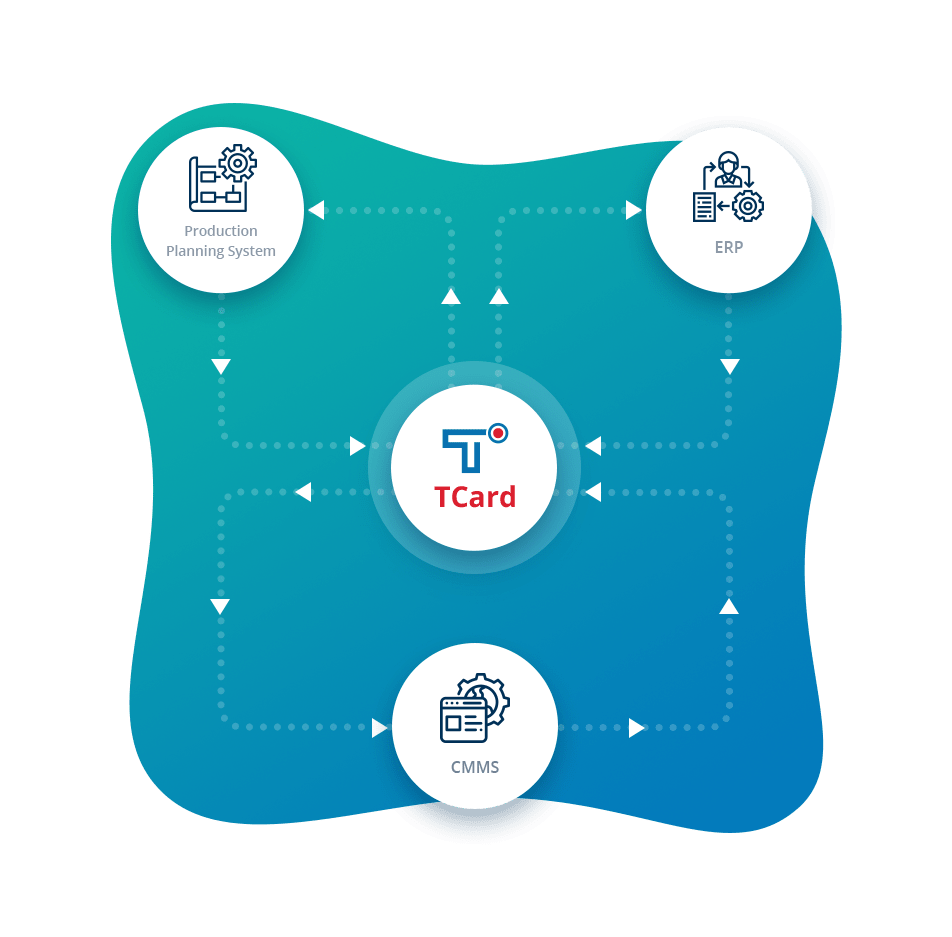

Data Synchronisation and MIS Integration

- Integrated Communication

- Automation

- Single Sign-On

- Data Consistency

- Rest API

T-Card is so dynamic to integrate with the other management information and ERP systems in the organisation. The Lean Assessment and Auditing system receives all the departmental data from the ERP system automatically using the REST API service.

- No Data Redundancy

- Increased Flexibility and Process Efficiency

- Centralised and Accessible Information

- Saves Data Entry Time of Employees

- Comprehensive Process Visibility and Integrated Operation

- Simplified IT Administration

- Cost and Storage-Saving

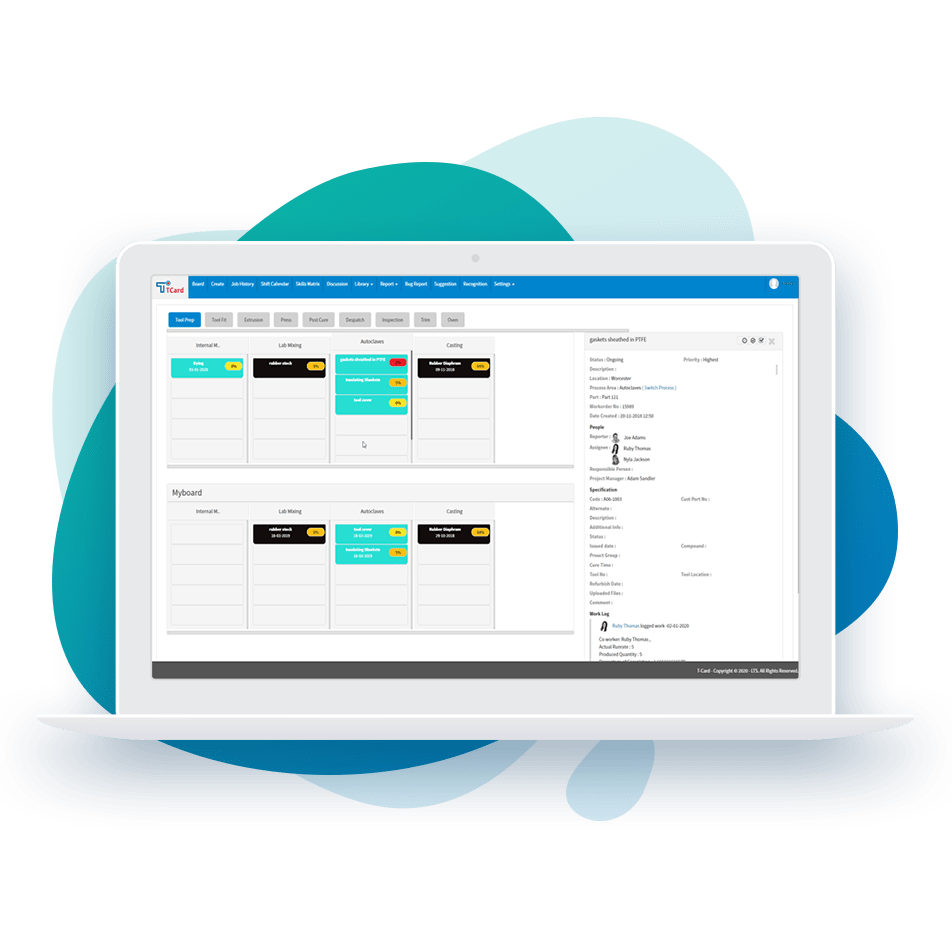

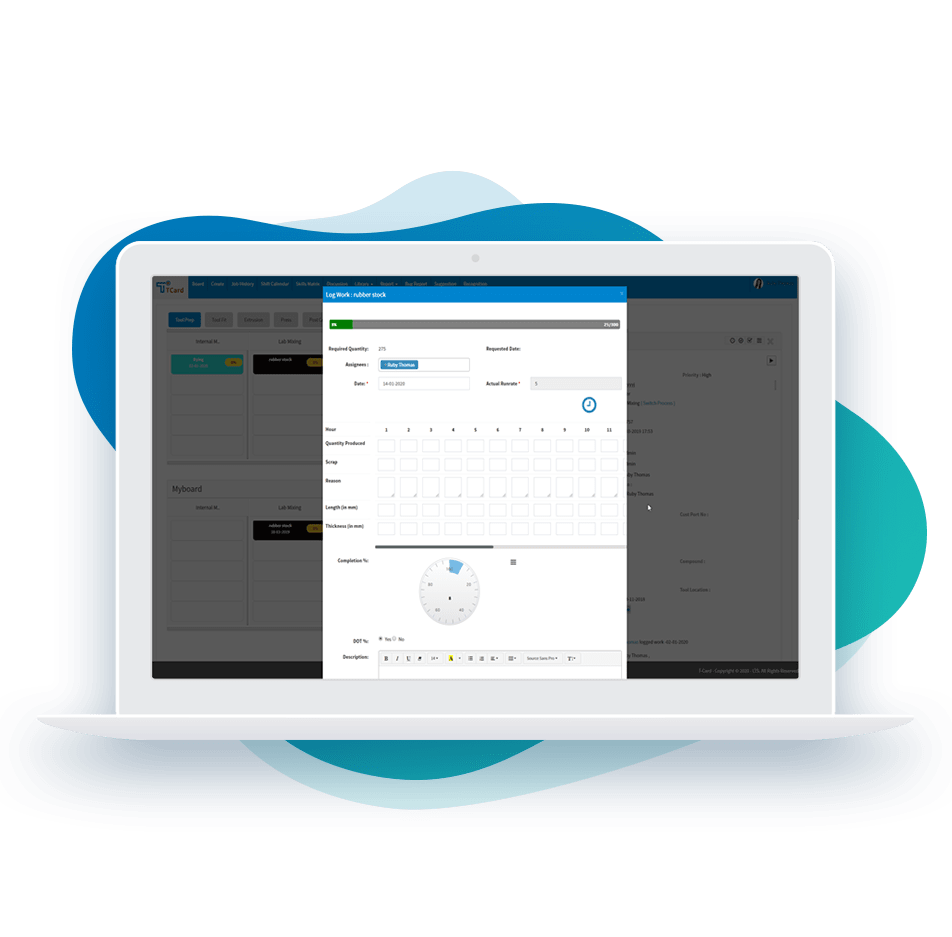

Work Order Management

- Work Order

- Timeline

- Checksheet

- Work Status

- Priority

- Switch Process

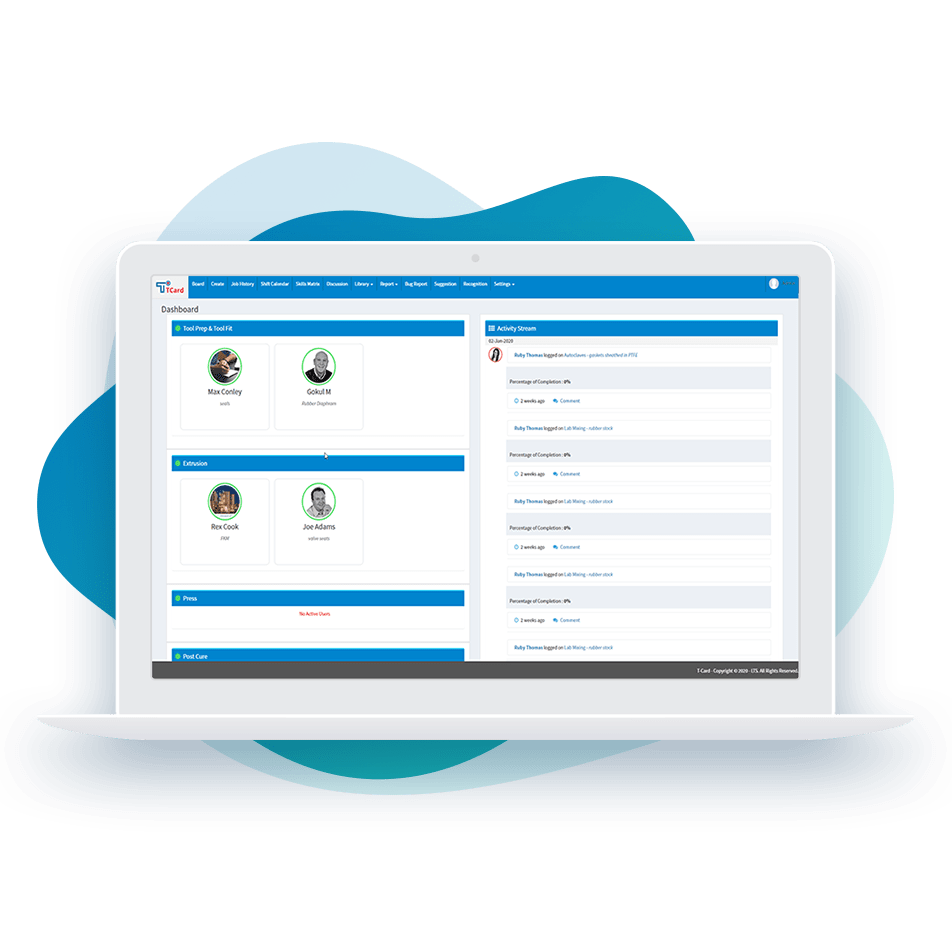

T-Card software effectively tracks and manages all work order information through a single dashboard and ensures all the processes are completed in the right way—every time. It provides a visual representation of the workflow, employee shift cycle, risk management, and reporting on downtime. Our T-card system allows manufacturers to easily create a work order, timeline activities, work status, and check sheet that helps them to improve the production process by optimising the process.

- Visual Work Order Management System

- Timeline Representation of the Workflow

- Checksheets to Ensure Quality

- Work Order Status and Percentage of Completion

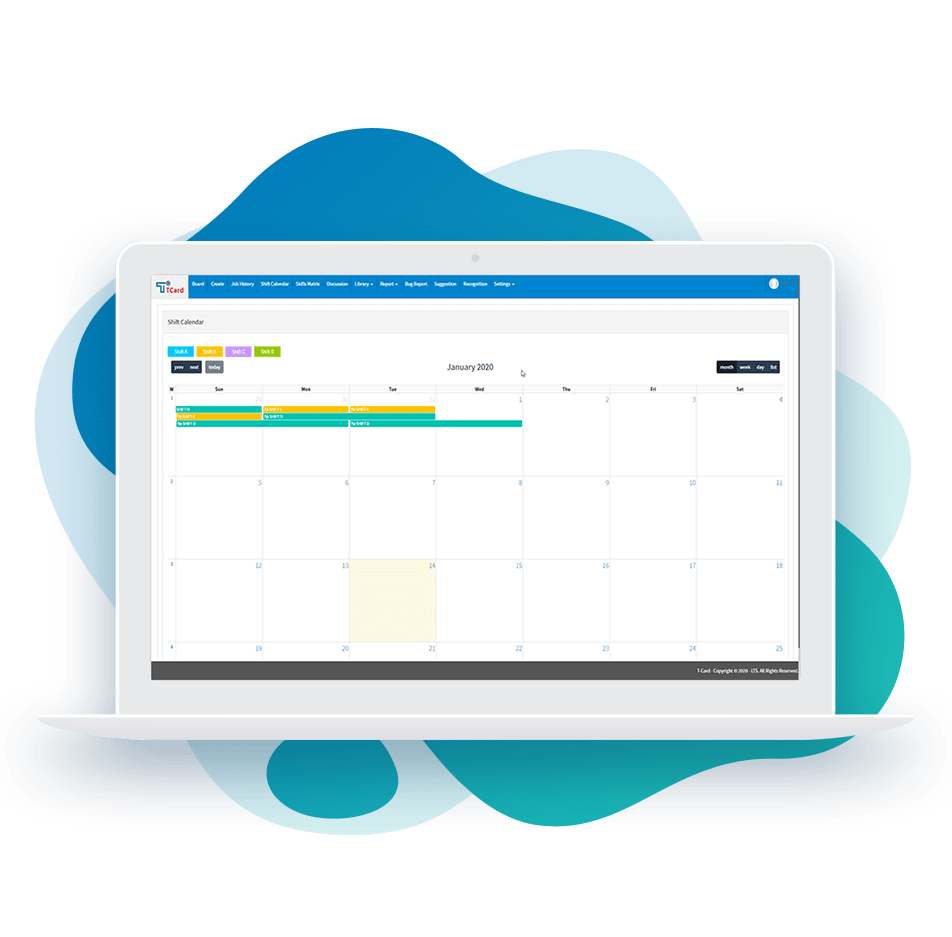

Employee Shift Cycle

- Shift Type

- Employee Shift Assign

- Shift Duration

- Shift Calendar

It is important to have a streamlined employee shift management process to ensure a smooth production flow in the factory. Employee Shift Management Module which enables the employer to effectively optimise their shift scheduling, planning, and shift calendar with utmost accuracy. Shift planner can track the employees in a shift and available resource in real-time.

- Planning the Shift Type

- Shift Timing Management and Shift Assign

- Work Shift Calendar with Shift Timing

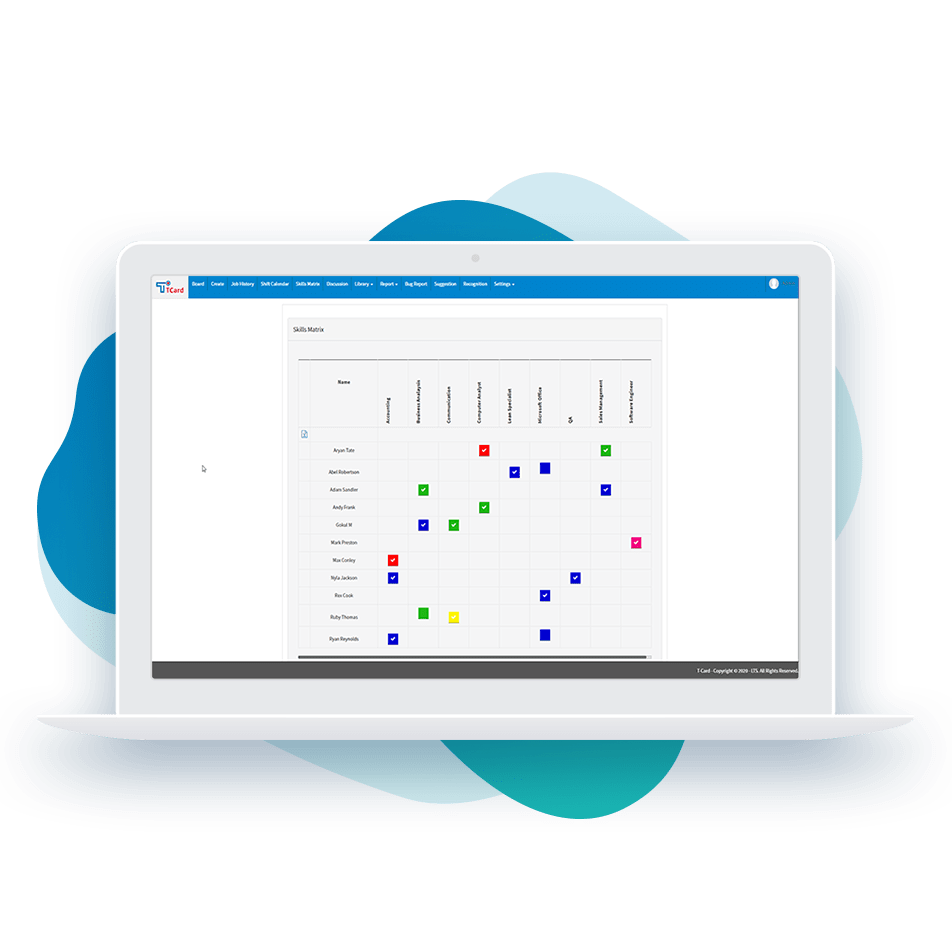

Job History, Skill Matrix and Risk Management

- Hazard Level

- Risk Ranking

- Track and Report Risk

- Risk Duration

Job history provides complete records of the job scheduled for each employee. Shift, working hours, and hazard level details can be quickly viewed by a single click. As the complexity of the risky task grows, there is a critical need for efficient ways of structuring the risk picture. Through this system, we can manage and control the risk in doing a task, efficiently improve decision making for assigning the employee in different shifts based on the risk level. From skill-matrix, employers can easily identify the employee skill levels in different operations.

- Hazard Level in Doing a Task

- Risk Analysis of Each Task

- Real-Time Accessibility and Insight

- Employee Skills and Availability

Scrap Reporting

- Scrap Analysis

- Scrap Reason

Scrap is a manufacturing reality impacting organisations across all industries and product lines. The scrap reporting option in T-Card system provides the ability to record, and analyse scrap reason that occurs during the production process.

- Recording Scrap Number and Scrap Reason

- Real-Time Scrap Reason Analysis