Lean Manufacturing Workshop

- Lean Manufacturing Workshop

- Principles of Lean

- The Seven Wastes of Lean

- 5S Visual Workplace

- Kanban Scheduling Systems

- Lean Six Sigma Green Belt

- Lean Six Sigma Black Belt

- Lean Change Management Workshop

- Lean for Leadership Workshop

Lean Manufacturing Workshop

Lean Manufacturing Workshop

- Terms & Terminology

- Lean Manufacturing

- Workflow

- Reduce Waste

- Lean Concepts & Tools

Lean wisdom enables the team to produce outstanding results such as minimise and eliminate waste, optimise workflow and continuously improve. The Lean Management Workshop helps you learn and leverage the wisdom of Lean. We can customise the scheduling and content of these sessions according to the organisational requirement. Lean Manufacturing Workshop gives you a comprehensive introduction to Lean concepts and tools.

- Understand the Terms & Terminology

- Benefits of Lean Manufacturing

- Conduct Value Stream Maps of the Current State

- Identify the Potentials for Reduced Waste and Improved Flow

- Develop a Future State Map

- Avoid the Common Pitfalls Encountered during Lean Implementation

Principles of Lean

- Lean Principles

- Value to Business

- Lean Culture

- Productivity

- Efficiency

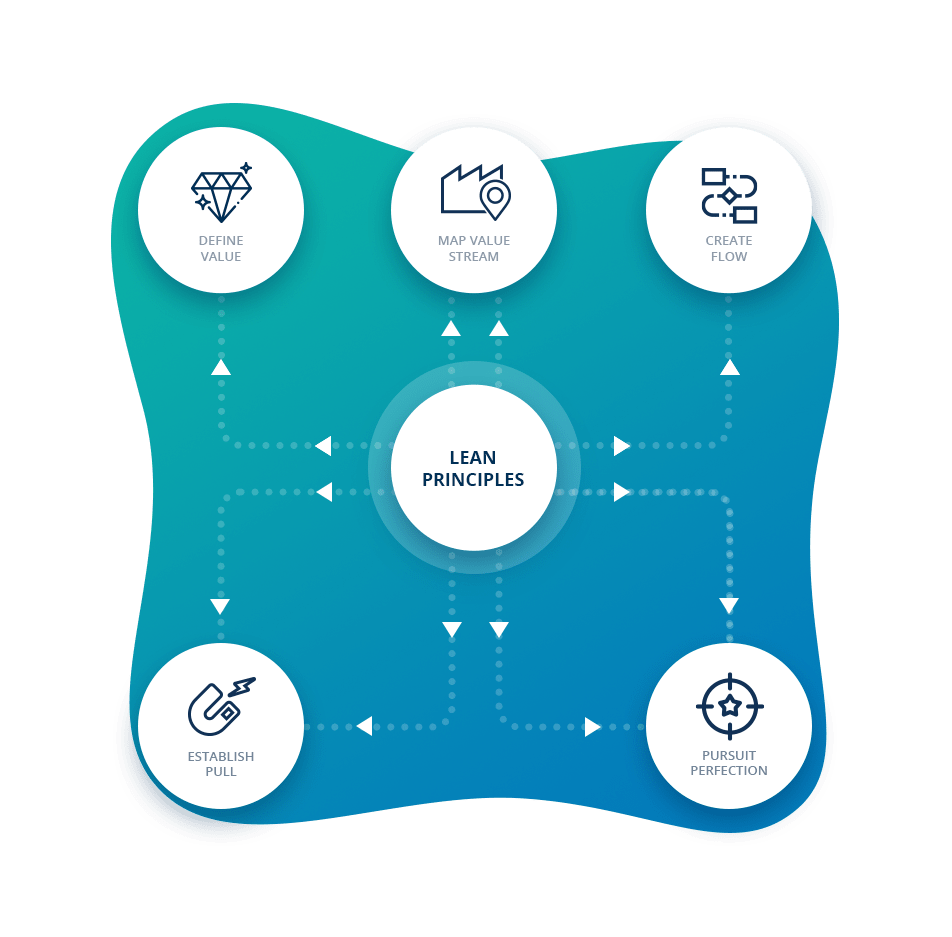

Through this workshop we train your employees on lean principles - the foundation of measurable progress in your organisation. Different aspects like efficiency, productivity, and overall workplace morale will be discussed in detail. Throughout the workshop the underlying principle of lean that is, the elimination of all forms of waste that don’t add value to the business is emphasised. We will enable your team to apply these Lean Principles and create a lean culture within your organisation.

- Lean Principles

- Productivity

- Efficiency

- Workplace Morale

- Lean Culture

- Add Value to Business

The Seven Wastes of Lean

- Seven Waste of Lean

- Productivity

- Efficiency

- Sustainable Development

- Tools to Eliminate Waste

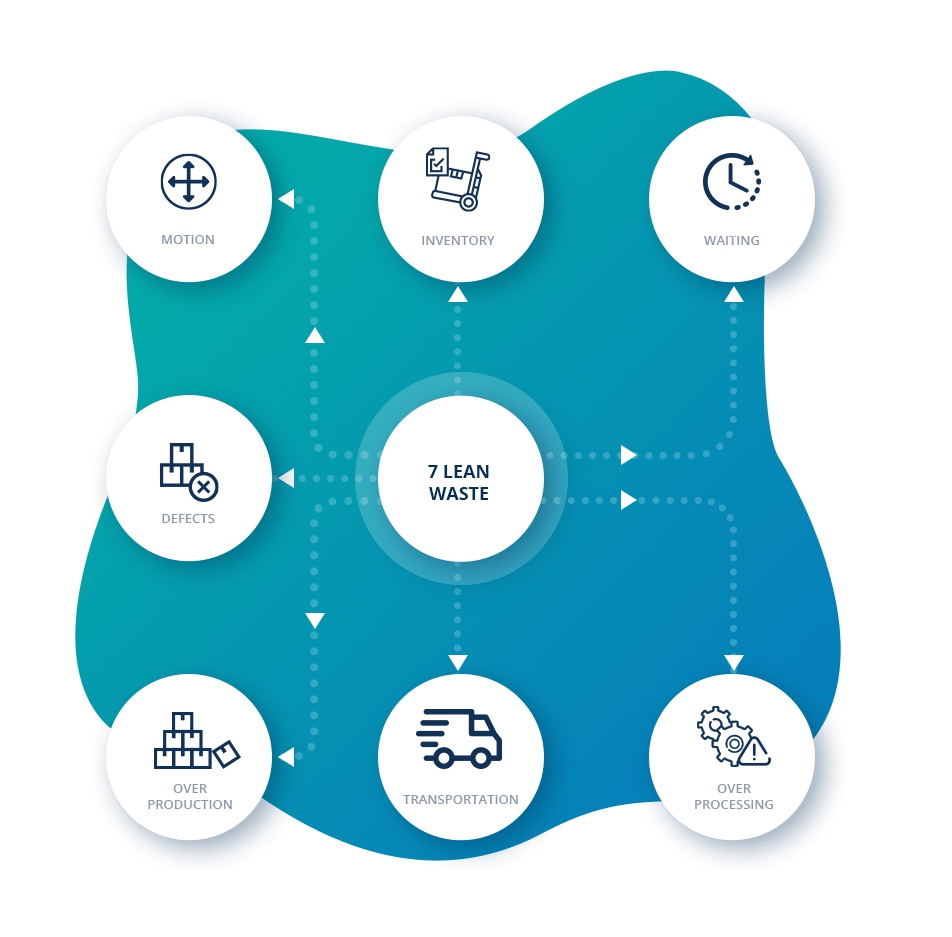

Motion, Inventory, Waiting, Defects, Overproduction, Transportation and Over-processing are the seven wastes of Lean. The workshop on the Seven Wastes of Lean will provide an overview of the seven different wastes and the ways to avoid them in the workplace to improve efficiency and productivity. Every employee in an organisation has the ability to identify and eliminate waste in their work. Through the workshop, we aim at empowering staff to be change agents by providing them adequate knowledge on the Lean waste and various methodologies to improve and be part of sustainable development.

- Identify the Seven Wastes in Your Work Area

- Explain Why Eliminating Waste is Critical to Profitability

- Basic Understanding of How Wastes take Root

- Learn the Tools to Eliminate the Wastes with Your Team

5S Visual Workplace

- Fundamentals of 5S

- Workplace

- Roadmap

- SORT

- SET

- SHINE

- STANDARDISE

- SUSTAIN

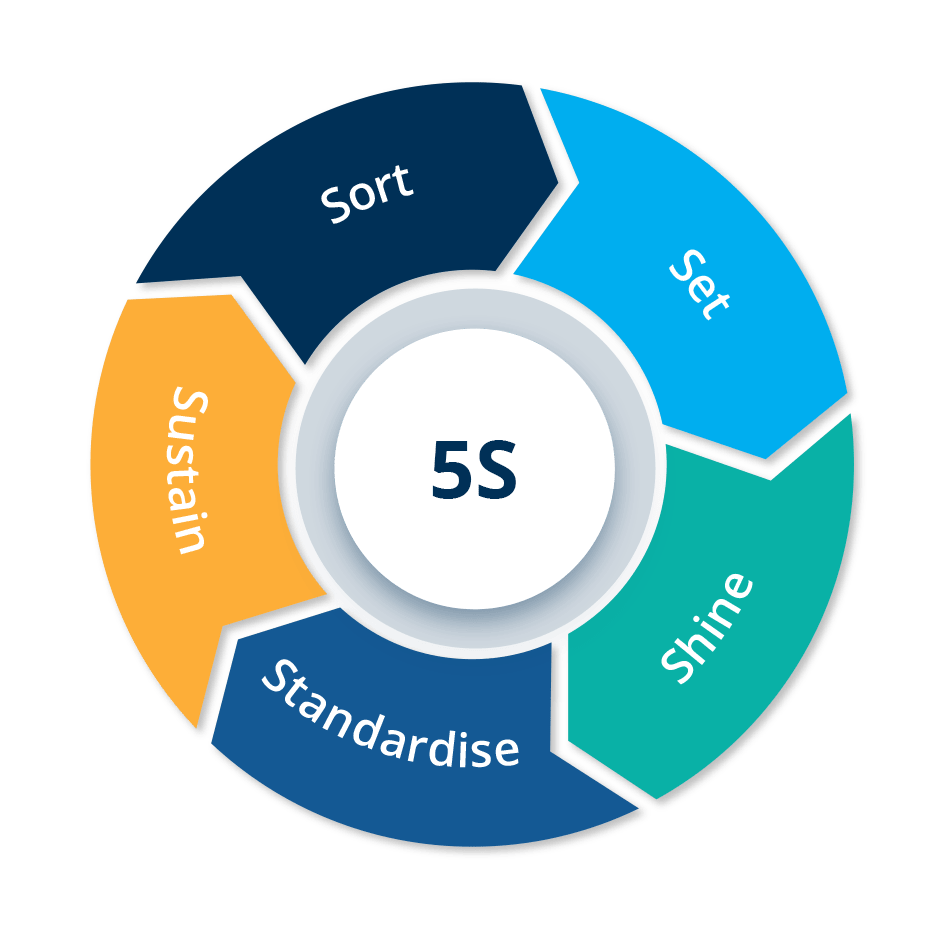

With the 5S Visual Workplace workshop, employees will learn the fundamental concepts of the 5Ss - SORT, SET, SHINE, STANDARDISE and SUSTAIN that will improve quality and productivity. The workshop will provide step-by-step guidelines for transforming the workplace into a 5S model. Transforming workspace from a cluttered, cramped area to a clean and highly functional space is the end result of the workshop. Helps evaluate 5S implementation in the workplace and ways to improve 5S processes.

- Understand each of the Five Ss and how each “S” Builds upon the Previous “S”

- Apply the 5Ss to their Work Area

- Develop a 5S Implementation Roadmap

- Instils Ownership of the Process in each Employee

Kanban Scheduling Systems

- Kanban Concepts

- Cultural Change Initiative

- Focus on Work

- Continuous Improvement

The Kanban Scheduling Systems Workshop provides guidance on Kanban implementation and bootstrapping a Kanban system in your own organisation. You will gain an understanding of how Kanban is a cultural change initiative and what that shift means, how Kanban can be applied to your software development workflow, and how it differs from other development methods. Kanban reduces the time spent on the wrong work and brings focus on the work that holds the right value.

- The Benefits of Kanban

- Kanban Concepts, Principles and Terminology

- Visualisation of Work

- Limiting Work-In-Process

- Analysing the Flow of Work

- Optimising Your Kanban System

- Continuous Improvement Culture

Lean Six Sigma Green Belt

- Six Sigma

- Tools & Methodologies

- Standards

- Performance

- Quality

- DMAIC Cycle

Six Sigma is a data-driven methodology that provides proven tools and techniques to help businesses streamline operations and provide customers with higher quality products and services. The primary focus is on eliminating defects and variations from organisational processes. The purpose of this workshop is to develop knowledge and skills in understanding and applying lean improvement methodologies with lean tools in order to identify and act on business improvements. The workshop will provide an overview of the tools and methodologies used and the various aspects like performance, standards, quality and DMAIC cycle.

- Basics of Six Sigma

- Step-by-step Process Required to Complete Six Sigma Projects

- Tools & Methodologies

- Performance

- Standards

- Quality

- DMAIC Cycle

Lean Six Sigma Black Belt

- Six Sigma

- Tools & Methodologies

- Leadership

- DMAIC Cycle

- Change Agent

- Standards

- Performance

- Quality

While those who hold a Green Belt or Black Belt often work closely together, they have distinctly different skill sets and roles on project teams. Education and training are key to the successful implementation of Six Sigma. Learning Six Sigma methodologies and applying it in the workspace has tremendous benefits for the future of any Business. Black Belt professionals act as a change agent in transformational six sigma projects. The workshop will provide an overview of the tools and methodologies used and the various aspects like performance, standards, quality, leadership and DMAIC cycle.

- Advanced Skills Required to be a Six Sigma Black Belt

- Review of Green Belt Techniques

- Tools & Methodologies

- Performance

- Standards

- Quality

- Leadership

- Change Agent

- DMAIC Cycle

Lean Change Management Workshop

- Leadership

- Change Adaptability

- Practical Tools

- Build Trust

- Commitment

- Positive results

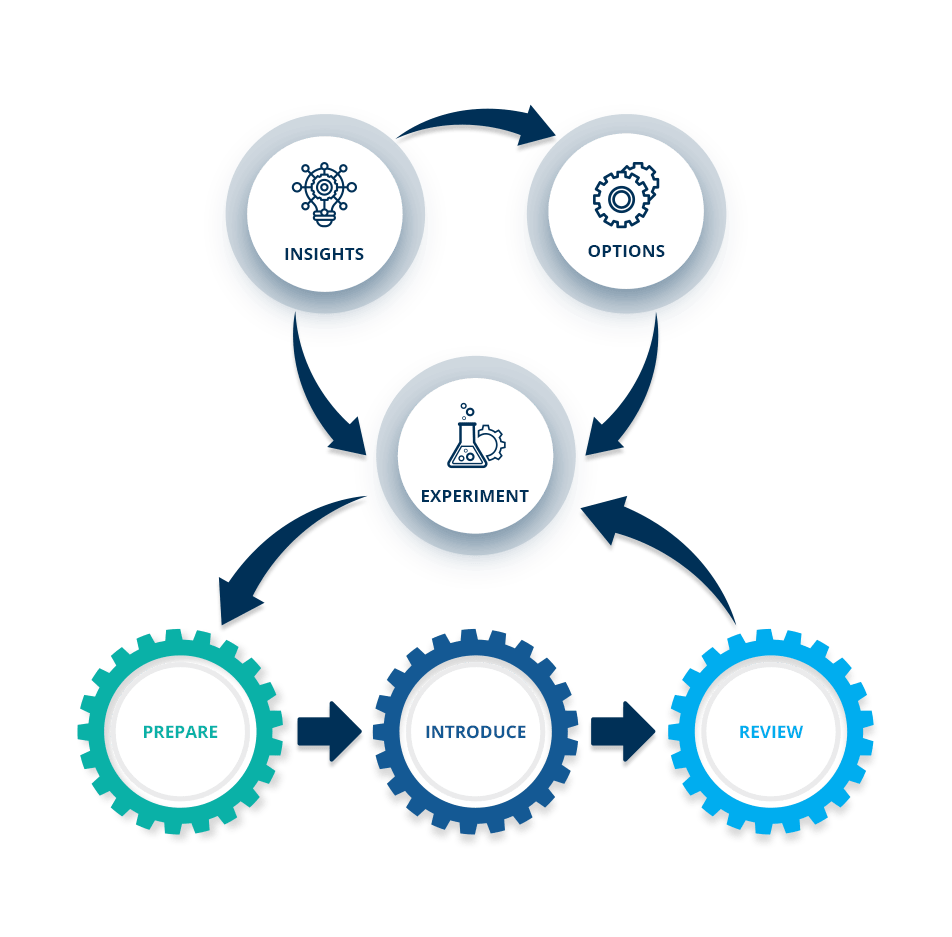

Change is inevitable in Lean culture. This workshop aims at providing an understanding of the need of a change within an organisation and the ways through which you can lead your team to get adapted to the change. Build trust, commitment, and positive results through any change initiative. This workshop will enhance your ability to help people overcome their reactions and get on board with new initiatives. You will be given practical tools that will enable you to manage the team and lead them through the change effectively.

- Understand Your Role as a Change Leader

- How Best to Respond

- Build Trust

- Increase the Readiness to Embrace Change

- Overcome Resistance in Your Work Environment

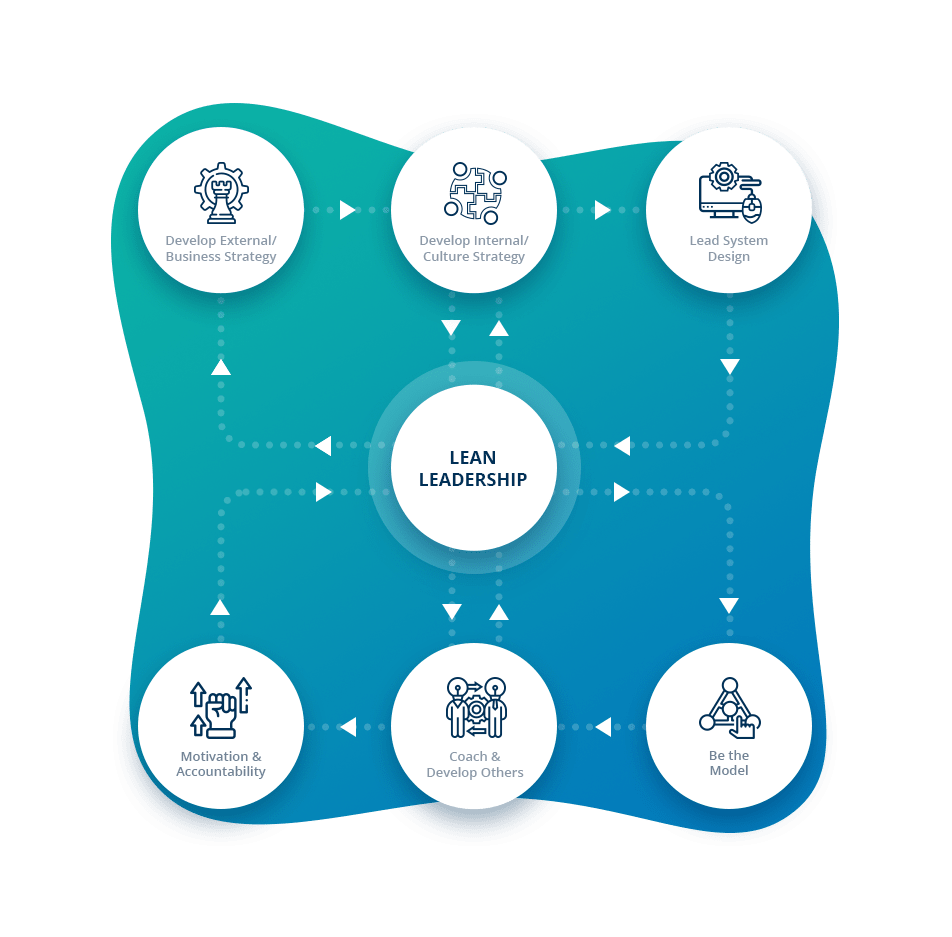

Lean Leadership Workshop

- Lean Strategy

- Empower Individuals

- Leadership

- Continuous Improvement

- Lean Thinking

This workshop will help leaders understand the differences between applying lean to their organisation vs integrating it into the business system. The workshop will analyse your current organisational strategies and identify the gap between where you are today and where you need to be. Leadership is key to successful implementation of lean strategies. We would empower individuals to take up personal leadership roles and practices, what a true leader does, how to identify the drawbacks within and ways to fill those gaps, so that the integration of lean will be more effective.

- What does Lean mean to Your Organisation?

- How to Sustain Lean?

- Culture of Continuous Improvement

- Lean Thinking

- Leadership Skills, Competencies and Capabilities