How to identify and eliminate the 8 lean wastes in your organisation?

- By Brett Griffiths

- Lean Technology

- September 14 , 2022

- Share

Waste isn't waste unless we waste it. The challenge lies in identifying the wastes in your business operations. Lean manufacturing aims to maximise the reduction of waste from any part of your production process. Waste in lean is any activity that has no role in enhancing the product's value or any unwanted strategies that can reduce the product's value, and the customer doesn't want to pay for it.

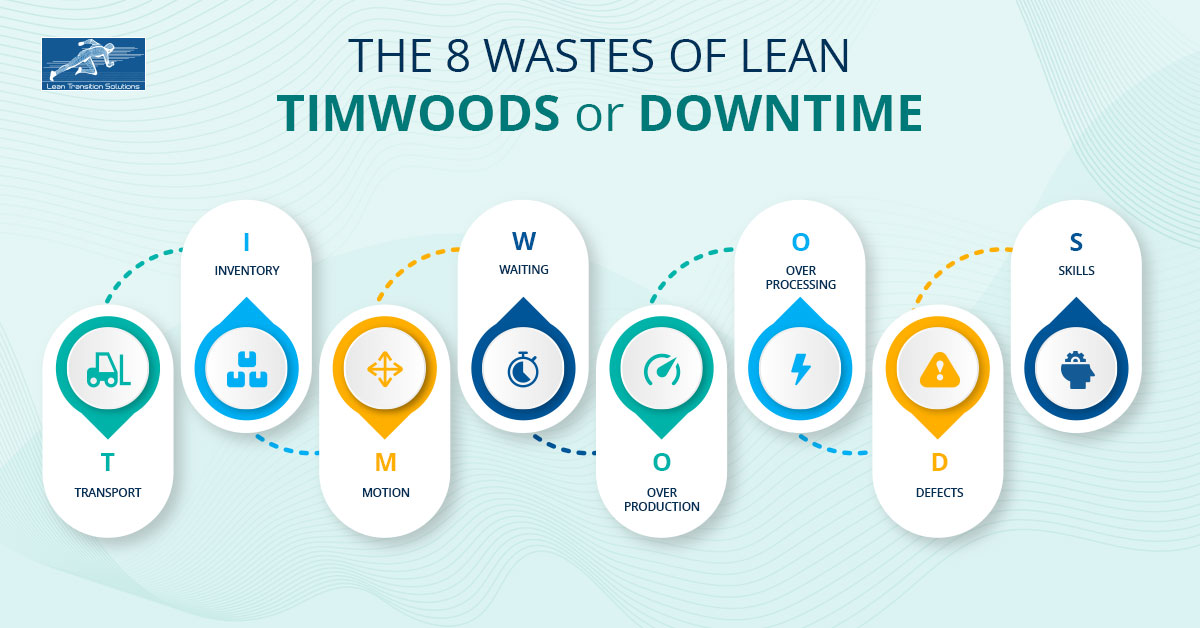

The 8 wastes of Lean

TIMWOODS or DOWNTIME? Doesn't sound familiar? These are the eight wastes or the mudas of lean.

-

T-Transportation

-

I-Inventory

-

M-Motion

-

W-Waiting

-

O-Overproduction

-

O-Overprocessing

-

D-Defects

-

S-Skills

-

D-Defects

-

O-Overproduction

-

W-Waiting

-

N-Non utilising Talent(skill)

-

T-Transportation

-

I-Inventory Excess

-

M-Motion

-

E-Extra processing

Let's see the 8 wastes with the examples that can help you identify these lean wastes in your organisation:

Transportation

Transportation is the process of transferring resources from one place to another. No value is added to the product here as it directly does not support immediate production. It also causes several other wastes like motion and waste, resulting in high overhead costs, unnecessary expenditures and irregular production flow.

Examples of transportation wastes :

-

Improper facility layout or an inadequate plant design

-

Poor production planning and poor scheduling

-

Poor workplace organisation

-

Moving equipment between distant facilities

-

Using a faraway supplier in place of a nearby one.

Inventory

Inventory waste happens when the product is created disproportionate to demand. Stockpiling of the inventories over the process requirements necessary in production in a Just in Time manner. The main reasons behind the inventory waste include imprecise forecasting systems, inefficient processes and suppliers, longer change over time, unbalanced production processes, and poor inventory tracking and management.

Examples of inventory waste :

-

Machinery that is seldom or never used

-

Storage of parts and products that have expired and cannot be used any longer.

-

Ordering extra parts that need to replace the outdated ones.

-

Overstocking in a way that does not meet the needs of the customer or does not add any value.

Motion

Motion waste is caused by unnecessary movement of goods and employees within the workplace that do not add value to the product. Ineffective plant layouts, lack of visual control, poor process documentation and poor workplace organisation.

Examples:

Reactive maintenance

Poorly located supplies and equipment

Excessive machine movement causing wear and tear

Processes taking lengthier steps than needed.

Excess activities cause the worker to search for missing tools and work instructions.

Gathering more tools than necessary.

Unnecessarily complicated procedures.

Waiting

Waiting waste occurs when there is an interruption to the smooth movement of the processes, people and goods. It can be caused by inconsistent work methods, lack of proper equipment and materials, long set-up times, low machine or man effectiveness, poor equipment maintenance and skill monopolies.

Examples:

Unplanned downtime or idle machinery

Man-made delays, either internally or externally.

Waiting time while the machine finishes the tasks.

Holding the products until the blocks in the ahead steps get resolved.

Overproduction

Producing more goods than are needed, faster than it is required or before it is needed causes overproduction. The customer does not pay for the idle time it is being placed. The primary reason behind the overproduction of waste is automation in the wrong places, lack of communication, local optimisation, low uptimes and poor planning.

Examples:

Unstable production scheduling

Inaccurate forecasting and demand information

Overstaffed warehouses and production facilities

Warehousing piling up with products that have not been sold.

Over-processing

Any effort in production or communication that does not add value to the product or the service is an over-processing waste. Doing more work or having more steps in a product or service than what is required by the customer is over-processing. It is caused by inappropriate decision-making, inefficient policies and procedures, lack of customer input concerning requirements, poor configuration control and spurious quality standards.

Examples:

Unclear specifications or quality standards

Installing a part or feature without estimating the demand

Slow and multilayered decision-making and approval processes.

Overabundance of product or feature options for what the customer needs.

Endless product and process refinement

Process bottlenecks

Defects

Defect waste is the value loss to do the scrap, repair, and rework of a product that deviates from specifications. The main reasons that cause the defect wastes are excessive variation in production processes, high inventory levels, inadequate tools or equipment, transport damage, incompatible processes, insufficient training and unnecessary handling.

Examples:

Not following the work instructions

Failing to follow the quality inspection process

Product shipped to the wrong customer

Inventory level of specific manufacturing materials not being accurately recorded.

Skills/ Unutilised Talent

The most damaging waste is the waste of human potential. The resources are not adequately utilised in the form of the people's experience, skills, knowledge and creativity. Making skilled employees do unskilled tasks is the underutilisation of resources. Failure to put the right people in the right seat and lack of proper process training are the main reasons behind the unutilised waste.

Examples:

Inoperative or misused machinery

Undertrained or mistrained labour

Weak or non-existent career development program

Lack of communication between leadership and staff.

Wastage of time on tasks that do not add value.

How to eliminate them?

Once you have identified the TIMWOODS or the DOWNTIME, start working on how to eliminate it.

Value Stream Mapping(VSM) is a lean management method that can help design the future by analysing the existing state of the company. It tracks the flow of the materials, gives a visual representation of the processes involved and the connection between them, and eliminates the activities that don't add value.

Determine actual waste sources and contribute towards reducing them.

Better communication and improved behaviour after identifying the waste help in not repeating it.

Prioritising results that add value for the customers.

Let's have a look at the other ways as well to eliminate these wastes:

Transportation

Creating an efficient workflow

Enforcing Work In Progress (WIP) limits.

Value stream mapping

Creating a U-shape production line

Inventory

Improving forecasting methods

Purchasing raw materials in required quantity only when needed.

Creating a queue system

Reducing buffers between production steps

Motion

Designing the workstation in a way that minimises the movement.

Ergonomically placing the equipment.

Waiting

Improve communication

Reduce waiting time

Overproduction

Scheduling and forecasting

Enforcing strict Work in Progress limits and monitoring using a Kanban or pull system

Following the Just in Time philosophy

Use Takt Time, reduce set up a time

Overprocessing

Understanding work requirements from a customer's standpoint

Use of modern tools, technologies and processes

Use value stream mapping

Defects

Using DMAIC to find the root cause of the problem

Design a process that can help in detecting defects during production itself.

Unutilised Talent

Using incentives for employees

Creating reward system

Technologies, management styles and training methods to engage employees.

Coaching, mentoring

Development streams

If you plan for a lean transformation in your organisation, waste reduction is your top priority. Waste is all around you, and you walk by it every day. While it is not easy to eliminate all waste in a single go, take a step forward. Identify them-TIMWOODS or DOWNTIME. Make sure your team has the same understanding of these. Try out the elimination steps. Create a better, safer environment for the people to work in and facilitate the team to identify new improvements.

Start Free Trial

LEAN TRANSITION SOLUTIONS

The Old Vicarage, Pershore Road, Upton Snodsbury, Worcester, Worcestershire, WR7 4NR, United Kingdom.

Lean Transition Solution

-

Lean Industry 4.0 Solutions

- TITAN:Computerised Maintenance Management System

- Data Point:Computerised Balanced Scorecard

- Janus: Automated Shop-floor Data Capture System

- T-Card: Integrated Production Planning and Plant Level Execution System

- JDI: Maintenance Automation App

- Maximus: Integrated ERP System

- e-Contractor: Integrated In-house Contractor Management System

- Q-Point: Integrated Quality Management System

- Safety-Point: Integrated Health and Safety Management System

- Lean Assessment: Lean Audit and Assessment System

- Saisho: Lean 5S Audit and Assessment App

- Emergency Response App: To Manage Emergency Situations

-

Leadership 4.0 Solutions

- Your Career Academy(YCA): Learning and Development System

- YCA e-Learning : Management System

- MentorYou(MU): Mentoring App

- Leadership 4.0 : Leadership Transformation Program

- Lean Manufacturing Workshop

- Lean Manufacturing Consulting

- ILM Accredited Green Belt Training and Certification Program

- ILM Accredited Black Belt Training and Certification Program

- Software Development Service

- Resources

- Company

- Contact