12 Lean Management Myths Explained: Separating Fact from Fiction

- By Brett Griffiths

- Lean Technology

- February 09 , 2026

- Share

Lean management has been around for decades, yet it’s still widely misunderstood. Many industries adopt Lean principles with good intentions, only to see limited impact because they’re working from outdated assumptions rather than true Lean thinking. From seeing Lean as a cost-cutting exercise to treating it as a one-time initiative, these misconceptions weaken its real value. In this blog, why Lean management myths are quite common, the cost of believing Lean management myths, 12 Lean management myths and reality, how leaders can apply Lean without falling for the myths, and how to support true Lean execution with the right systems.

Why Lean management myths are quite common

Lean management is typically misunderstood because it’s usually introduced as a set of tools or initiatives rather than a long-term way of thinking. When companies stress on quick wins – such as isolated improvement projects, cost reduction targets, or tool rollouts – Lean becomes transactional instead of transformational. Over time, this fuels Lean management myths that dilute its actual purpose and impact.

Several factors contribute to this confusion:

- Lean is reduced to cost cutting: Early Lean efforts often prioritise headcount reduction or efficiency targets, developing the false belief that Lean is about doing more with less, rather than delivering more value with minimal waste.

Tools are mistaken for the system: Visual boards, 5S, and value stream maps are beneficial, but without the right mindset and leadership behaviours, they become rituals rather than drivers of improvement.

Unclear leader ownership: Lean is frequently assigned to CI teams, which strengthens the myth that Lean is a specialist operation rather than a leadership responsibility.

Short-term implementation mindsets: Treating Lean as a project with an end date result in surface-level adoption, missing the cultural and behavioural change needed for sustained results.

One-size-fits-all thinking: Applying Lean rigidly across various teams or environments builds resistance and feeds the belief that Lean doesn’t work outside manufacturing or stable operations.

Understanding why these misconceptions exist is clearly the first step to overcoming them – moving towards a more practical, people-centred, and results-driven approach to Lean management.

The cost of believing Lean management myths

When Lean management myths mould decisions, organisations don’t just misunderstand Lean – they actively limit its potential. Instead of allowing better flow, faster decisions, and engaged teams, Lean becomes a source of frustration, resistance, and delayed improvement. Eventually, these misconceptions translate into very real business costs.

Common impacts include:

Low ROI from Lean initiatives: When Lean methodology is treated as a toolbox or short-term programme, developments remain isolated, delivering temporary gains rather than sustained performance.

Employee disengagement and resistance: Cost-cutting narratives and rigid implementations erode trust, reinforcing the belief that Lean is “done to” teams rather than built with them.

Poor leadership alignment: Allotting Lean to CI teams weaken accountability, slow decision-making and disconnecting strategy from daily execution.

Fragmented improvement efforts: Teams optimise locally instead of end-to-end, creating silos that increase handoffs, lags, and rework.

Missed opportunities for adaptability: Industries trapped in lean management myths struggle to respond to change, seeing Lean as too rigid instead of a system that supports flexibility.

Ultimately, the greatest cost isn’t inefficiency – it’s losing confidence in Lean itself. Breaking free from these myths enables companies to refocus on value, learning, and long-term improvement.

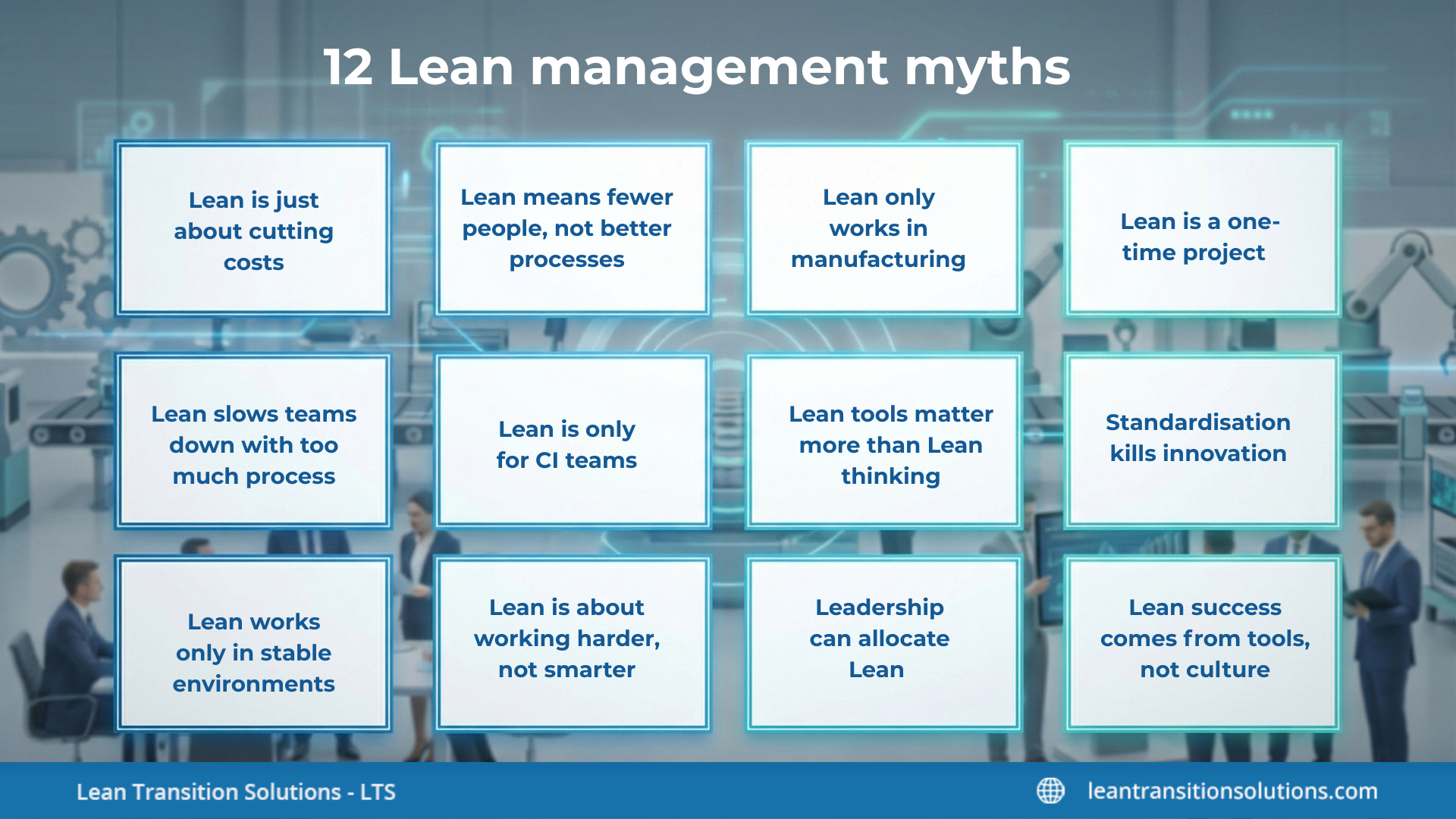

Myth vs. Reality: 12 Lean management myths explained

Lean usually fails not because the principles are faulty, but because they’re misunderstood. These twelve Lean management myths underline where industries go wrong – and what Lean actually looks like in practice.

- Myth: Lean is just about cutting costs

- Myth: Lean means fewer people, not better processes

- Myth: Lean only works in manufacturing

- Myth: Lean is a one-time project

- Myth: Lean slows teams down with too much process

- Myth: Lean is only for continuous improvement teams

- Myth: Lean tools matter more than Lean thinking

- Myth: Standardisation kills innovation

- Myth: Lean works only in stable environments

- Myth: Lean is about working harder, not smarter

- Myth: Leadership can allocate Lean

- Myth: Lean success comes from tools, not culture

Reality: Lean pinpoints on maximising customer value by removing waste. Cost reduction is a result of better flow and quality – not the starting point.

Reality: Lean improves processes, so people spend less time firefighting and more time adding value. It's about smarter work, not lesser people.

Reality: While Lean began in manufacturing, its principles apply equally to services, healthcare, IT, finance, and knowledge work.

Reality: Lean is a long-term management system. Sustainable results come from continuous learning and improvement, not one-off initiatives.

Reality: Done right, Lean simplifies work. Clear standards minimise confusion, rework, and delays – enabling teams to move faster.

Reality: Lean succeeds when leaders and frontline teams own it together. CI teams support Lean; they don’t run it.

Reality: Tools allow improvement, but mindset drives it. Without the right behaviours and leadership, tools quickly lose impact.

Reality: Standard work builds stability, freeing teams to experiment, solve problems, and innovate where it matters most.

Reality: Lean thrives in change. By making problems visible and workflows flexible, Lean assists companies adapt faster.

Reality: Lean eliminates unnecessary effort. The goal is better outcomes with less waste, not increased pressure on teams.

Reality: Leadership commitment is non-negotiable. Lean requires leaders to model behaviours, remove barriers, and align teams daily.

Reality: Culture sustains Lean. Without trust, engagement, and accountability, even the best tools fail to deliver lasting results.

How leaders can apply Lean without falling for the myths

Leaders play a defining role in whether Lean becomes a sustainable management system or another short-lived initiative. Applying Lean effectively needs moving beyond tools and slogans and focusing on behaviours, systems, and lean management practices that strengthen true Lean thinking.To apply Lean without falling for common Lean management myths, leaders should:

Start with purpose, not cost targets: Anchor Lean efforts around customer value, safety, quality, and flow. Cost improvements will follow naturally.

Lead Lean visibly and consistently: Lean cannot be assigned. Leaders must model problem-solving, spend time where work occurs, and strengthen improvement daily.

Focus on systems, not isolated tools: Use tools to assist end-to-end flow, decision-making, and learning – not as standalone activities.

Build capability at every level: Equip teams with problem-solving skills and the confidence to enhance their own work, rather than depending on specialists.

Standardise to stabilise, then improve: Establish clear standards to construct a baseline, then encourage teams to challenge and develop them continuously.

Measure what drives behaviour: Shift from delaying, output-only metrics to visual, practical measures that guide day-to-day actions.

Treat Lean as a long-term discipline: Embed Lean into routines, reviews, and leadership expectations to make sure it survives beyond initial rollouts.

When leaders apply Lean in this manner, myths lose their grip – and Lean becomes a practical, people-centred system for delivering lasting results.

Supporting true Lean execution with the right systems

Sustaining Lean needs more than intent and good practices – it depends on having systems that strengthen visibility, alignment, and accountability at every level. This is where Lean Transition Solutions (LTS) software and tools play a vital role in turning Lean thinking into daily execution.

LTS allows industries to move beyond scattered spreadsheets and static boards by offering a linked digital environment for Lean management. Through live visibility and structured routines, leaders and teams can see what matters, act faster, and continuously improve.

Core ways LTS supports true Lean execution include:

Data Point Balanced Scorecard software: Supports Lean by translating strategy into computable objectives and cascading KPIs across levels. It improves focus, alignment, and performance visibility – crucial to effective Lean Daily Management and fact-based decision-making.

Digital TCard system Allows visual workflow management by making work, priorities, and bottlenecks visible. It supports flow, limits work-in-progress and improves coordination during daily huddles and team reviews.

Kamishibai Audit Board: Strengthens standard work and discipline by structuring routine process audits. It aids leaders ensure adherence to standards, spot gaps early, and sustain improvements on the shopfloor.

Janus Data Capture: Gives live shopfloor data to replace assumptions with facts. It assists problem detection, equipment performance tracking, and continuous improvement through accurate OEE and operational insights.

CMMS (Computerised Maintenance Management System): Supports Lean maintenance by shifting teams from reactive to preventive and predictive practices. It enhances equipment dependability, lowers unplanned downtime, and stabilises processes critical to flow.

Saisho 5S Audit and Assessment App: Sustains workplace organisation by standardising 5S audits and monitoring progress over time. It helps maintain visual control, minimise waste, and embed 5S as an ongoing discipline rather than a one-off activity.

Moving beyond Lean management myths requires more than correcting misunderstandings – it calls for a fundamental shift in how Lean is led, applied, and sustained. When organisations stop treating Lean methodology as a toolkit or short-term initiative, it becomes a powerful system that aligns people, processes, and performance around real value. For leaders, this means replacing myths with clarity: prioritising purpose over cost, systems over silos, and learning over quick fixes. Planted into daily management and strengthened through the right behaviours and visibility, Lean moves beyond individual effort to become the way the firm functions – every day, at every level – delivering continuous improvement that adapts, engages teams, and produces quantifiable results over time.

FAQs

1. How long does it take to see results from Lean management?

Lean delivers early visibility within weeks, but meaningful, sustained results typically emerge over several months as behaviours, routines, and systems mature.

2. Can Lean management work in small or mid-sized organisations?

Yes. Lean is often easier to implement in smaller organisations due to fewer layers, faster decision-making, and closer leadership involvement.

3. What is the difference between Lean management and Six Sigma?

Lean focuses on flow, waste reduction, and value delivery, while Six Sigma targets variation reduction and defect control. Many organisations combine both approaches.

4. Do you need certified Lean experts to implement Lean successfully?

No. While expertise helps, Lean succeeds through leadership commitment, practical problem-solving, and team involvement rather than formal certification alone.

5. How does Lean management support employee engagement?

Lean gives teams ownership of problems, visibility into performance, and a voice in improvement – key drivers of motivation and engagement.

6. Is Lean management suitable for remote or hybrid teams?

Yes. With the right digital systems, Lean principles such as visual management, daily alignment, and continuous improvement translate effectively to remote environments.

7. What metrics are most important in Lean management?

Lean prioritises flow, quality, delivery reliability, and problem resolution over purely output or utilisation-based metrics.

8. How does Lean management support decision-making?

Lean enhances decision-making by making performance, issues, and trends visible early – enabling teams and leaders to act before problems escalate.

9. Can Lean management coexist with agile or OKR frameworks?

Yes. Lean complements agile and OKRs by providing operational discipline, stability, and continuous improvement beneath strategic goal-setting frameworks.

10. Why do Lean initiatives lose momentum over time?

Most lose momentum due to inconsistent leadership behaviours, lack of visibility, or treating Lean as an initiative rather than an operating system.

Start Free Trial

LEAN TRANSITION SOLUTIONS

The Old Vicarage, Pershore Road, Upton Snodsbury, Worcester, Worcestershire, WR7 4NR, United Kingdom.

Lean Transition Solution

-

Lean Industry 4.0 Solutions

- TITAN:Computerised Maintenance Management System

- Data Point:Computerised Balanced Scorecard

- Janus: Automated Shop-floor Data Capture System

- T-Card: Integrated Production Planning and Plant Level Execution System

- JDI: Maintenance Automation App

- Maximus: Integrated ERP System

- e-Contractor: Integrated In-house Contractor Management System

- Q-Point: Integrated Quality Management System

- Safety-Point: Integrated Health and Safety Management System

- Lean Assessment: Lean Audit and Assessment System

- Saisho: Lean 5S Audit and Assessment App

- Emergency Response App: To Manage Emergency Situations

-

Leadership 4.0 Solutions

- Your Career Academy(YCA): Learning and Development System

- YCA e-Learning : Management System

- MentorYou(MU): Mentoring App

- Leadership 4.0 : Leadership Transformation Program

- Lean Manufacturing Workshop

- Lean Manufacturing Consulting

- ILM Accredited Green Belt Training and Certification Program

- ILM Accredited Black Belt Training and Certification Program

- Software Development Service

- Resources

- Company

- Contact