What is Lean Transformation ?

- By Brett Griffiths

- Lean Technology

- April 28 , 2024

- Share

Have you ever wondered how some businesses achieve remarkable efficiency and sustainable growth while others struggle to keep up? The answer lies in the transformative power of Lean thinking and Lean manufacturing processes. At the core, Lean manufacturing streamlines shop floor activities, eliminates waste – or "muda" – in all its forms, and drives continuous improvement in operational activities.

Across the globe, industrial professionals offer specialised Lean transformation programs for organisations, guiding manufacturers through process improvement and continuous improvement. These Lean transformation training sessions can equip manufacturers with the right tools and mindset needed to thrive amidst fierce competition. But what exactly is Lean transformation, and why is it crucial for the success of modern businesses? The key concepts discussed in this blog can clear all your doubts and answer your queries relating to Lean transformation.

What is Lean Transformation?

Lean transformation is a systematic methodology for process improvement to address organisational or team-level challenges through strategic changes. Lean transformation marks a fundamental shift in the organisational mindset and operational strategies, deeply rooted in the principles of Lean thinking. At its essence, Lean transformation seeks to optimise processes, eliminate inefficiencies, and enhance efficiency, ultimately fostering sustainable business growth. The Lean transformation process drives operational excellence by maximising the flow of value delivery and shifting ahead of conventional business practices. The five focus areas of the Lean transformation process include:

- Identifying value streams to understand customer needs and eliminate non-value-added activities.

- Streamlining processes to eliminate waste, improve process flow and reduce lead times.

- Implementing pull systems like Kanban, to drive production based on customer demand.

- Emphasising continuous improvement through Kaizen initiatives.

- Building a culture of employee empowerment and engagement to sustain Lean practices.

Why is Lean Transformation important?

Lean transformation is crucial for any business to achieve operational excellence by maximising value delivery and adapting to customer demands and market trends. By adopting Lean principles, businesses can optimise resource utilisation, enhance customer satisfaction, and remain competitive in a dynamic market environment. Lean transformation fosters a continuous improvement culture, empowering teams to identify and address inefficiencies proactively. Through Lean transformation, organisations can streamline operational processes, eliminate waste, and boost efficiency, ultimately driving sustainable growth.

Lean Transformation Model

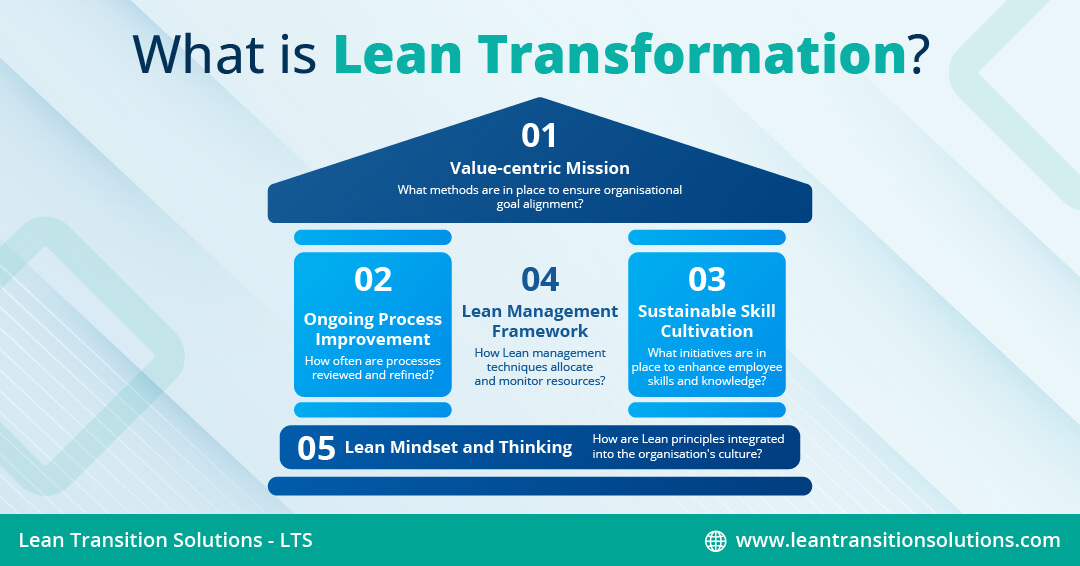

The Lean Transformation Model is a dynamic framework embraced by successful organisations worldwide. Lean transformation approach is not a one-size-fits-all solution but a strategic initiative tailored to each organisation's unique needs and challenges. Whether it's Lean business transformation in manufacturing, automobile, energy, electronics, healthcare, banking or service industries, Lean principles remain universal, offering a roadmap for success. While approaches may vary, five essential components consistently define successful Lean transformations:

- Value-centric Mission: What methods are in place to ensure organisational goal alignment?

- Ongoing Process Improvement: How often are processes reviewed and refined?

- Sustainable Skill Cultivation: What initiatives are in place to enhance employee skills and knowledge?

- Lean Management Framework: How Lean management techniques allocate and monitor resources?

- Lean Mindset and Thinking: How are Lean principles integrated into the organisation's culture?

What are the steps for Lean Transformation ?

Embarking on a Lean transformation journey can be pivotal to unlocking operational excellence and sustainable growth within your organisation. This Lean Transformation Roadmap outlines seven essential steps to be taken in your Lean transformative journey.

- Step 1- Current State Assessment: In the initial phase of Lean transformation, organisations comprehensively assess their current operational state. This involves identifying areas of inefficiency, waste, and bottlenecks within processes. By analysing workflows and value streams, businesses gain valuable insights into opportunities for improvement, laying the foundation for subsequent Lean initiatives.

- Step 2- Ensuring Leadership Commitment: A crucial aspect of a Lean transformation is securing an unwavering commitment from organisational leadership. Leaders must advocate the Lean philosophy, embody its key principles, and foster a continuous organisational improvement culture. By actively supporting Lean initiatives and providing resources, executives set the tone for success and ensure alignment across all levels of the organisation.

- Step 3- Equipping Employees with Lean Skills: Effective Lean management transformation relies on empowering employees with the necessary knowledge and skills. Through targeted training and education programs, staff members are equipped with Lean methodologies, tools, and techniques. This ensures everyone within the organisation is aligned with the Lean production system and can actively contribute to Lean product management.

- Step 4- Implementation of Lean Tools and Techniques: With foundational knowledge in place, organisations move towards implementing Lean tools and techniques practically. This phase involves deploying strategies such as lean 5S manufacturing, Value Stream Mapping (VSM), and Kanban to optimise processes and eliminate waste. Businesses can improve efficiency and performance by applying Lean manufacturing principles in their organisations.

- Step 5- Streamlining Processes within a Single Service: Lean practitioners analyse the unique aspects of each service or process and select appropriate tools accordingly. For instance, while some services may benefit from the visual workflow management of Kanban boards, others might require different lean methodologies. By understanding the specific needs and dynamics of each service, organisations can effectively deploy Lean tools to achieve optimal results.

- Step 6- Analyse and Optimise the Workflow: An essential aspect of lean transformation involves defining metrics to measure progress and success. Lean Metrics such as Order Defect Rates (ODR), Cycle Time, and Inventory Turnover Ratio offer crucial process efficiency and effectiveness indicators. Through consistently measuring and monitoring these Lean metrics, organisations can pinpoint improvement areas and optimise Lean initiatives accordingly.

- Step 7- Integrating Stable Workflows from Multiple Services:Extending value stream mapping throughout the organisation, from product management to direct customer value delivery, enhances visibility and efficiency. By integrating stable workflows from various services into a cohesive process map, organisations can identify bottlenecks and optimise operations wherever needed. Additionally, fostering collaboration across departments promotes synergy and enables continuous improvement initiatives to be applied holistically.

- Step 8- Embracing Continuous Improvement: Lean transformation is an ongoing journey characterised by a commitment to continuous improvement. Through the Plan-Do-Check-Act (PDCA) cycle, organisations systematically identify opportunities, implement lean conversions, evaluate results, and adjust strategies accordingly. Lean culture transformation is a constant process that ensures that Lean management principles remain ingrained in the organisation's culture, driving sustained improvement and adaptation to changing market conditions.

Tools and Techniques for accelerating Lean Digital Transformation

- 5S Audit and Assessment Software: Organise workspaces through Sort, Set in Order, Shine, Standardise, and Sustain practices and digital 5S audits for improved efficiency and cleanliness.

- T Card Software: Track workflow progress using T-shaped cards in digital format to enhance task management and visual control.

- Balanced Scorecard Software: Utilise the Balanced Scorecard framework to measure track and manage strategic performance across key areas of the organisation.

- Kanban Software: Implement visual workflows and limit Work in Progress (WIP) to optimise productivity and workflow management.

- Just-in-Time (JIT) Production: Reduce inventory levels and lead times by producing goods only as needed to meet customer demand.

- Poka-Yoke (Error Proofing): Integrate mechanisms to prevent errors at the source, enhancing product quality and reliability.

- Andon Systems: Utilise real-time visual displays to provide visibility into production status and facilitate immediate problem-solving.

Lean methodology offers a comprehensive toolkit for streamlining operations and maximising efficiency. Know more about other lean manufacturing or management tools that can revolutionise shop floor processes on the blog: Top 25 Lean Manufacturing Tools

The top 5 reasons why Lean Transformation fails

Lean transformation processes may fail in organisations due to insufficient commitment from leadership, inadequate training, ineffective communication, reluctance to embrace change, and setting unrealistic expectations.

A successful Lean transformation journey begins with a Lean transformation plan that outlines initiatives, goals, responsible individuals, desired timelines for execution, and expected results from those Lean initiatives within your organisation. Avoiding common pitfalls in the Lean transformation process is essential for achieving desired outcomes after implementing Lean practices. Remember these critical points the next time you start your Lean transformation journey within your organisation.

- Unclear comprehension of Lean Principles: Lack of clarity regarding the foundational principles of Lean methodology can hinder the effectiveness of Lean transformation efforts. It's essential to grasp Lean principles thoroughly to align strategies with organisational goals and drive meaningful change.

- Implementing many Lean Initiatives at a time: Rushing to deploy numerous Lean initiatives simultaneously can overwhelm the organisation, shifting the focus away from core Lean objectives. It's crucial to prioritise initiatives strategically, ensuring a systematic approach to implementation.

- Exclusion of employees from the Lean Transformation process: Neglecting employee involvement in the Lean journey can undermine morale and hinder buy-in. Engaging employees at all levels creates a sense of accountability and empowers them to contribute their insights, ultimately driving greater success in Lean initiatives.

- Failure to measure the outcomes of Lean Transformation: Without establishing lean metrics and tracking progress, you won't recognise the actual impact of your lean efforts. It's important to define Key Performance Indicators (KPIs) and regularly assess the results to measure the effectiveness of Lean initiatives and make informed adjustments as needed.

- Abandonment of Lean Initiatives too fast: Expecting immediate results and abandoning Lean goals too fast can undermine the value of the transformation process. Embracing the principles of slow, iterative, and continuous improvement is necessary for long-term success in Lean transformation, allowing for sustained progress and adaptation over time.

How long does Lean Transformation take?

The duration of a Lean transformation strategy varies significantly depending on factors such as the organisational size, complexity, and commitment level. While some improvements may be realised in weeks or months, achieving full-scale Lean maturity requires several years of dedicated effort. It's crucial to understand that Lean transformation is an ongoing journey of continuous improvement, adaptation and consistency. Organisations can drive sustained long-term success by prioritising incremental progress and fostering a culture of Lean principles.

Top Benefits of Lean Transformation

Implementing Lean and digital transformation methodologies in your organisation can offer many advantages, from enhancing efficiency to driving customer satisfaction. Let's explore the key benefits that lean transformation initiatives could bring to your organisation.

- Enhanced operational efficiency

- Reduction of waste and non-value-added activities

- Improved quality and customer satisfaction

- Increased productivity and throughput

- Streamlined processes and workflows

- Cost savings and resource optimisation

- Agile and responsive to market changes

- Empowered and engaged workforce

Lean Transformation Example: TRP Sealing Systems' Lean Transformation Journey

TRP Sealing Systems recognised the need to boost efficiency and productivity on their shop floor, prompting them to embark on a Lean transformation journey.

Previously reliant on manual methods and paper-based spreadsheets alongside their ERP system, TRP acknowledged the constraints of these traditional approaches. To overcome these limitations, they partnered with Lean Transition Solutions Ltd. to adopt digital lean management tools.

Integrating solutions like the Digital T Card System and Janus Data Capture, TRP experienced a significant shift in operations. The Digital T Card System automated work order allocation, optimising production planning and execution by leveraging real-time machine availability data. This led to accelerated work order completion and an enhanced Overall Equipment Efficiency (OEE).

Janus Data Capture provided TRP with comprehensive insights into their manufacturing processes, empowering them to eliminate non-value-added activities and make data-driven decisions, which are crucial elements of lean transformation.

With the implementation of the Data Point Balanced Scorecard, TRP visualised strategic objectives, monitored Key Performance Indicators (KPIs), and aligned their workforce with preset goals, fostering a culture of continuous improvement.

TITAN CMMS was introduced for computerised maintenance management, facilitating the creation and tracking of maintenance requests to support Total Productive Maintenance (TPM) goals and further improve OEE.

Additionally, by leveraging the Saisho 5S audit and assessment app, TRP monitored performance and ensured ongoing enhancements aligned with their lean transformation objectives.

By adopting digital lean manufacturing tools, TRP Sealing Systems optimised shop floor operations, boosted productivity, and positioned itself for sustained growth in a competitive market landscape.

Wrapping up, you may have probably understood that Lean transformation is not merely a set of tools or techniques; it represents a fundamental shift in mindset and approach towards business operations. It embodies the philosophy of continuous improvement and waste elimination, aiming to create “a Lean organisation”- capable of adapting to change and driving sustained growth.

Through the strategic use of Lean manufacturing tools and techniques such as 5S methodology, Kanban systems, and JIT (Just In Time) production, organisations can optimise workflows and minimise waste. Moreover, utilising digital solutions like Balanced Scorecard software and 5S audit software further accelerates the Lean transformation process. Ultimately, a holistic approach to Lean transformation fosters a culture of innovation and continuous improvement, positioning organisations for long-term success in today's competitive landscape.

Start Free Trial

LEAN TRANSITION SOLUTIONS

The Old Vicarage, Pershore Road, Upton Snodsbury, Worcester, Worcestershire, WR7 4NR, United Kingdom.

Lean Transition Solution

-

Lean Industry 4.0 Solutions

- TITAN:Computerised Maintenance Management System

- Data Point:Computerised Balanced Scorecard

- Janus: Automated Shop-floor Data Capture System

- T-Card: Integrated Production Planning and Plant Level Execution System

- JDI: Maintenance Automation App

- Maximus: Integrated ERP System

- e-Contractor: Integrated In-house Contractor Management System

- Q-Point: Integrated Quality Management System

- Safety-Point: Integrated Health and Safety Management System

- Lean Assessment: Lean Audit and Assessment System

- Saisho: Lean 5S Audit and Assessment App

- Emergency Response App: To Manage Emergency Situations

-

Leadership 4.0 Solutions

- Your Career Academy(YCA): Learning and Development System

- YCA e-Learning : Management System

- MentorYou(MU): Mentoring App

- Leadership 4.0 : Leadership Transformation Program

- Lean Manufacturing Workshop

- Lean Manufacturing Consulting

- ILM Accredited Green Belt Training and Certification Program

- ILM Accredited Black Belt Training and Certification Program

- Software Development Service

- Resources

- Company

- Contact