Lean Manufacturing Consulting

- Manufacturing Consulting

- Lean Culture

- Gemba Walk

- Lean Six Sigma

- Lean Manufacturing Assessment

- Visual Management

- Value Stream Mapping

- Lean Diagnostic Study

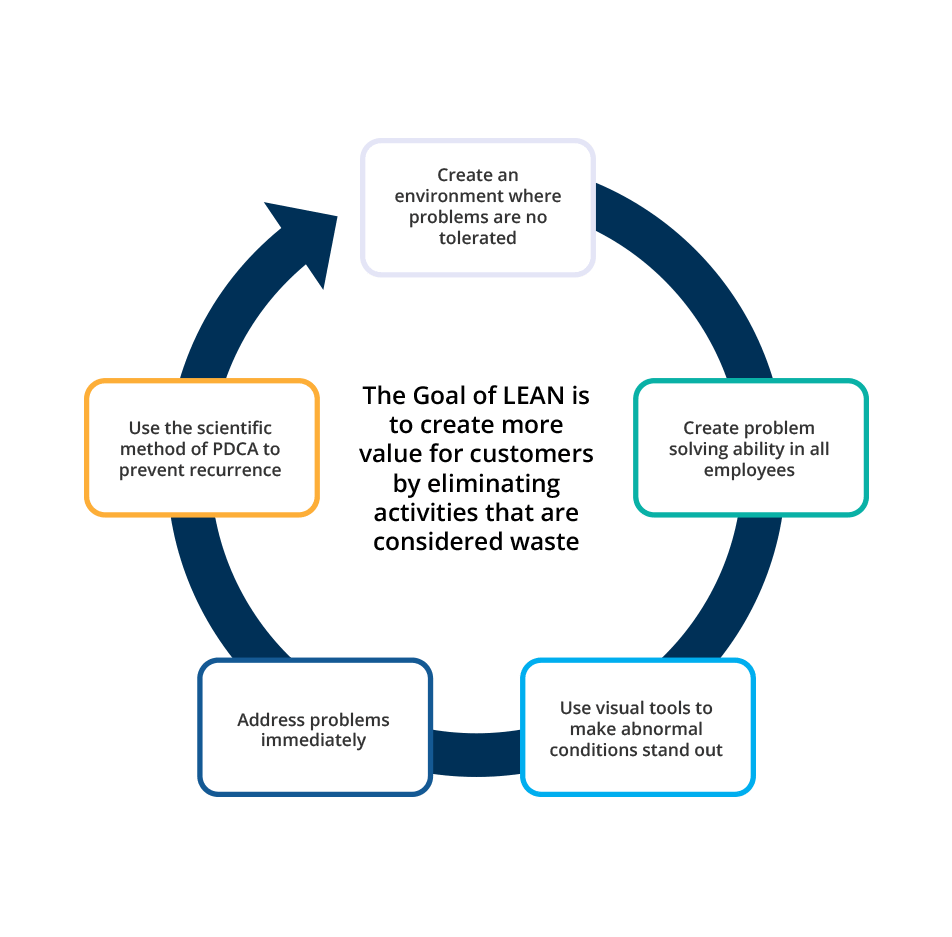

Lean Manufacturing Consulting

Manufacturing Consulting

- Consulting

- Lean

- Sustainable Growth

- Operational Excellence

Our expertise in Lean Manufacturing Consulting helps companies solve issues using lean methodologies and make rapid changes in performance and convert those changes into sustainable and profitable growth. Organisations can leverage operational excellence by adapting to a lean environment. We have subject matter experts who understand the foundation, framework and implementation of lean manufacturing and supply chain programs. With their expert advice on the change management process, organisations can successfully implement lean programs that are scalable and sustainable. We help you understand lean and where you are, implementing customised lean production systems and ways to improve performance over the long term.

- Lean Manufacturing Consulting

- Expert Advice

- Improve Performance

- Change Management

- Successful Implementation

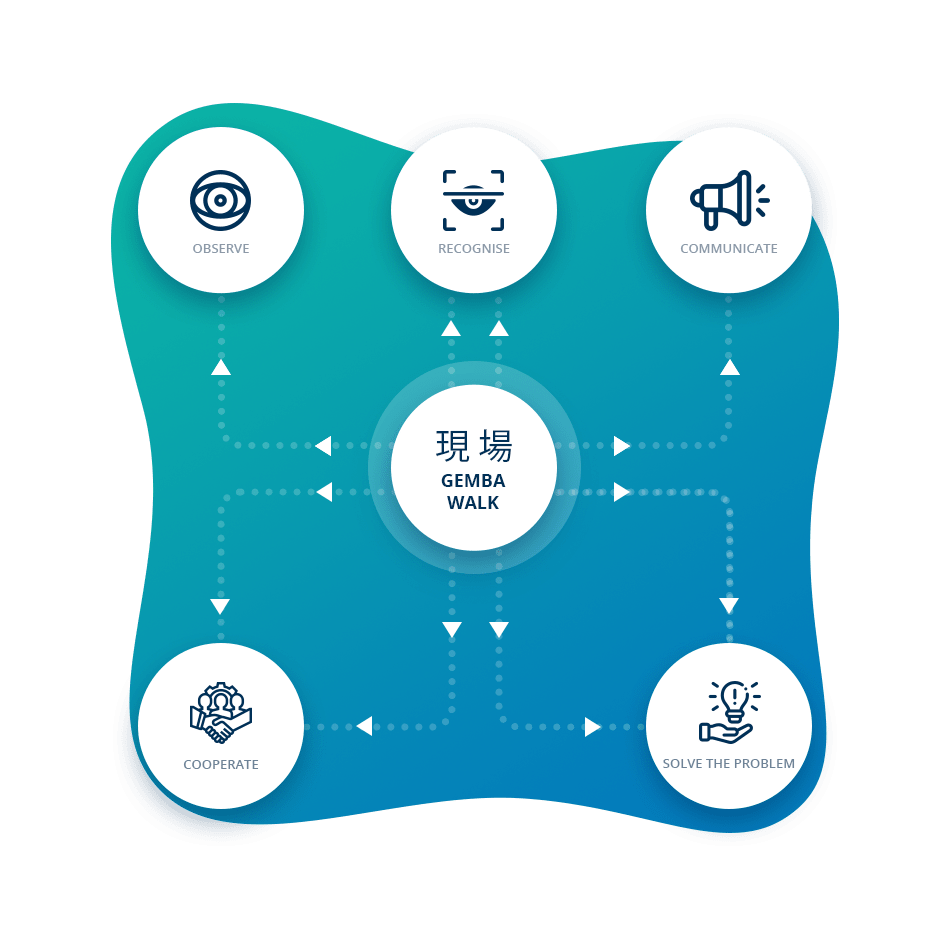

Gemba Walk

- Lean Practices

- Workplace Visit

- Lean Leaders

- Improvement Strategies

Gemba walks are a fundamental part of Lean management philosophy. Gemba walks help you understand the ground level reality and the problems faced. Our team of experts will visit organisations and walk the floor of their workplace to identify wasteful activities.

Gemba Walk is one of the five Lean guiding principles that should be practiced by Lean leaders on a daily basis. Gemba walks maintains Lean practices and drives further improvement within the organisation. Gemba Walk Team will analyse your existing strategies and gives suggestions for overall development.

- Walk through Workplace

- Analyse Lean Practices

- Organisation Visit

- Ground Level Reality

- Overall Development

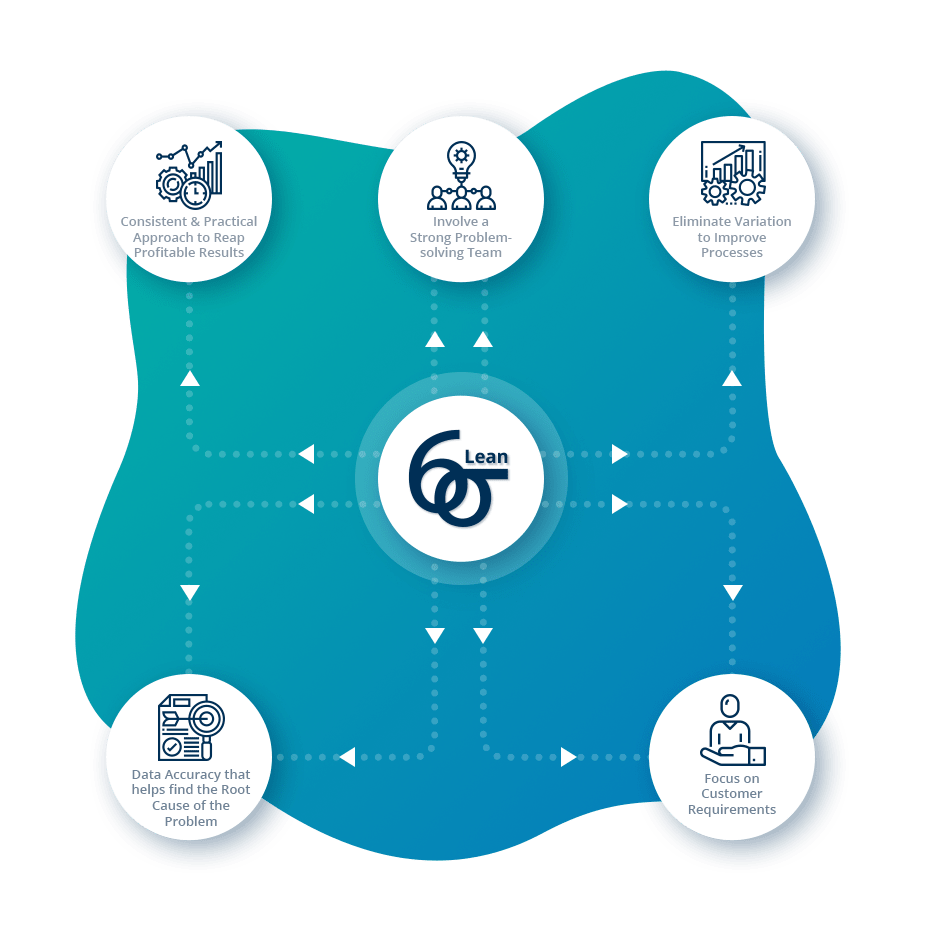

Lean Six Sigma

- Six Sigma

- Eliminate Waste

- Education & Training

- Streamline Process

Lean Six Sigma approach seeks to improve performance by eliminating waste and defects. It combines Six Sigma methods and tools and the lean manufacturing practices to eliminate waste of any kind, physical resources, time, effort and talent while assuring quality in production and organisational processes. The primary focus of Six Sigma is on eliminating defects and variations from organisational processes. Education and training are key to the successful implementation of Six Sigma. Learning Six Sigma methodologies and applying it in the workspace has tremendous benefits for the future of any business.

- Eliminate Waste

- Enhance Productivity

- Benefits for Future Business

- Assure Quality

- Training

Lean Manufacturing Assessment

- Assessment

- Global Standards

- Business Strategy

- Manufacturing Practices

Lean Manufacturing Assessment will look closely at a company’s supply chain (raw material to delivered product) and identify how it performs against global standards. The assessment focuses on speed, quality, cost and sustainability. We analyse how well positioned the supply chain is with respect to the organisation’s objectives. It will help in reviewing the existing business strategy and identifying the gap between the current practices and global best manufacturing practices. We will provide short-medium-long term recommendations to the organisation for implementing lean manufacturing practices and better supply chain performance.

- Business Strategy

- Global Standards

- Lean Assessment

- Better Performance

- Best Practices

Visual Management

- Visual Workplace

- Process Overview

- Track & Evaluate

- Corrective Measures

Visual Management is an essential tool in the world of Lean and can be seen as the link between the data and the people. Visual Management will enable organisations to identify problems, reduce waste, reduce production costs, shorten lead times, reduce inventory, create a safe working environment and even increase profits. It provides clarity at a glance. Tracking and evaluating the team and their performance, the ways to improve the process, all can be controlled using visual management. Visual workplace makes it possible to get an overview of the entire process that takes place and helps in taking and implementing corrective measures.

- Visual Workplace Management

- Overview of All the Processes

- Track & Evaluate Team Performance

- Clarity at a Glance

- Implement Corrective Measures

Value Stream Mapping

- Value Stream Map

- Business Processes

- Long Term Improvement

- Plan & Perform

Value Stream Mapping provides a clear view of how various business processes are related to each other, assesses the need for those processes and how efficient they really are. During Value Stream Mapping, a model is created which shows how much time, effort and cost is required for a specific process. This will enable people to plan and perform accordingly. Value Stream Mapping changes the way employees think about the processes. It gets into the details of how a process really works, how to improve each process and tools and skills required to implement long term improvement within the organisation.

- Value Stream Map Model

- Business Processes

- Insight to Bottlenecks in Any Business

- Identifies Organisational Issues

- Long Term Improvement

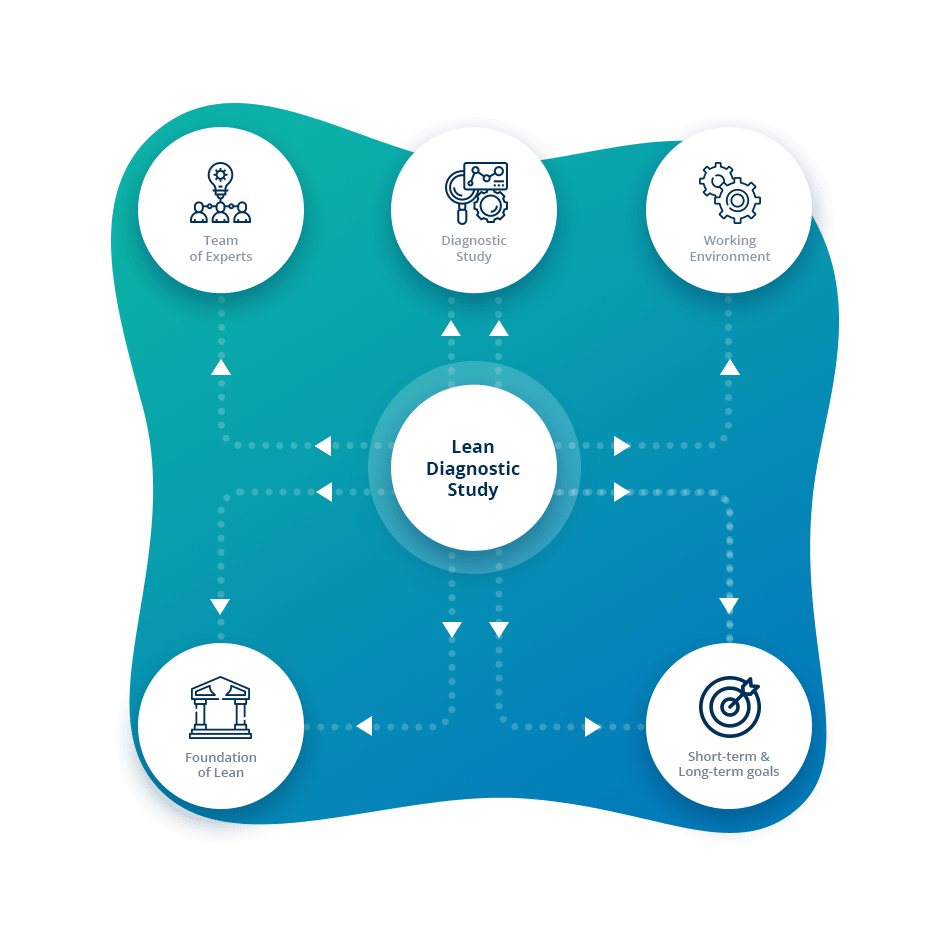

Lean Diagnostic Study

- Evaluate Business Strategy

- Effective Implementation of Lean

- Lean Principles

- Lean Practices

Lean Diagnostic Study is conducted by a team of experts who will analyse and generate reports according to the specific working environment of an organisation. This report will help organisations evaluate their current business strategies and practices. The report will incorporate the suggestions put forth by the lean experts which will help in planning and achieving short-term and long-term goals. This diagnostic process acts as a foundation for lean principles and practices to build upon.

- Team of Experts

- Diagnostic Study

- Working Environment

- Foundation of Lean

- Short-term & Long-term Goals